The mining industry is a vital pillar of industrial development, providing raw materials for various industries by extracting valuable components from mineral resources. In this process, the ball mill plays an indispensable role and is one of the essential machines in the iron ore industry.

The ball mill operates by crushing, grinding, and mixing ores through the action of steel balls rotating inside the mill. When the cylindrical mill rotates, the ores are carried along with the steel balls. It is through the process of mutual collisions, friction, and wear that the ores are ground down to the desired particle size. The efficiency of the grinding process within the ball mill is influenced by a variety of parameters. These include the size of the steel balls, the type of balls used, the filling ratio of these balls within the mill, and the speed at which the cylinder rotates.

Therefore, mining companies must carefully select and adjust relevant equipment details according to the specific characteristics of the ore being processed. For example, the type of grinding media, the amount of media to be filled, and the speed of the mill.By doing so, they can optimize the grinding effect when the ball mill is in operation. This careful selection and adjustment are crucial for achieving the best possible grinding results.

The ball mill boasts a significant advantage in terms of its high efficiency and energy-saving capabilities. Its capacity for continuous operation ensures the stability of the mineral processing procedure. This is crucial for maintaining a consistent output and avoiding interruptions in the production line.

In addition, using optimized grinding media and advanced control systems in the mill helps reduce energy consumption. Low energy consumption reduces operating costs. Reduced consumption also helps achieve environmental sustainability. These optimizations increase productivity. Ball mills become an important piece of equipment to improve the efficiency of mineral processing operations.

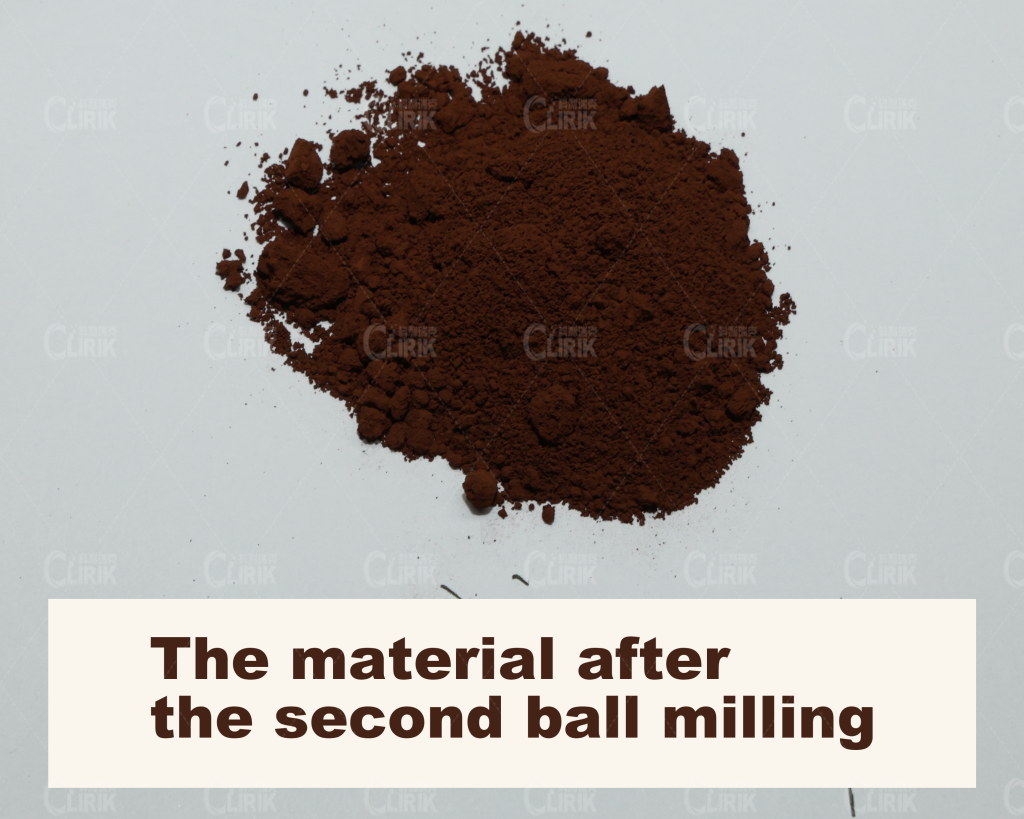

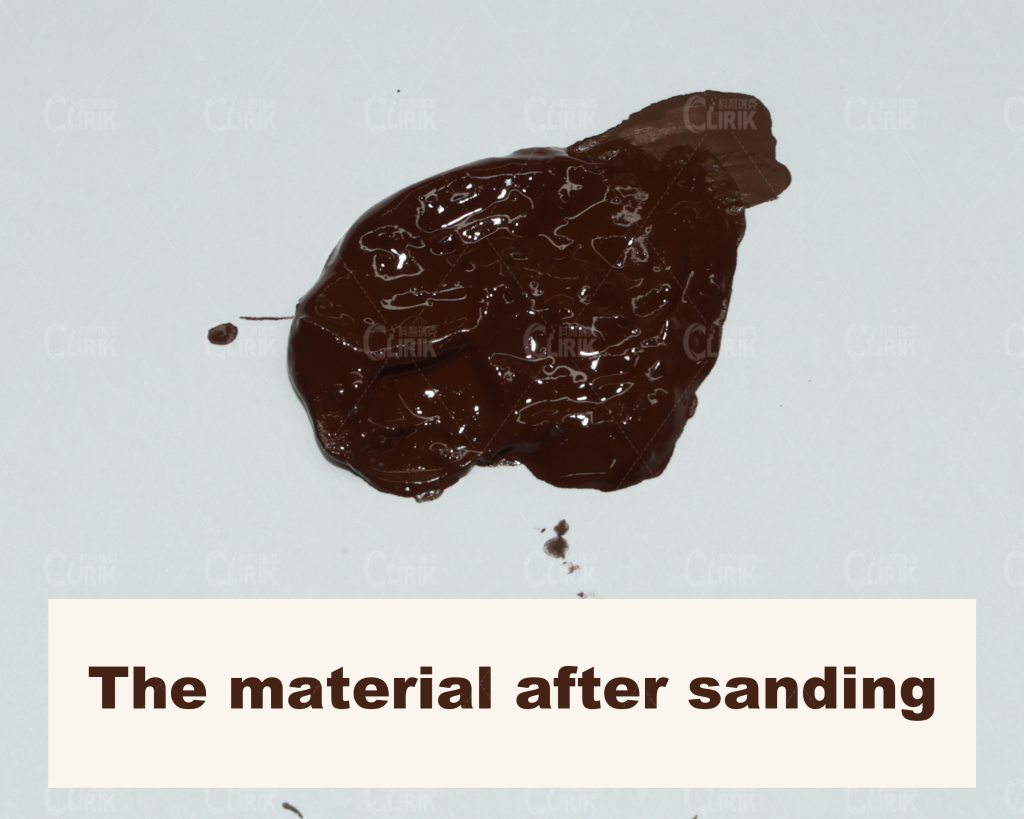

Ball mills are crucial in various mineral processing scenarios. These mills have the ability to adapt to the processing demands of ores with varying degrees of hardness. By making adjustments to the grinding media and the duration of the grinding process, the mills can achieve the necessary level of fineness. In the context of iron ore processing, ball mills serve a dual purpose. Firstly, they are employed in the pretreatment phase to crush the ore into a particle size that is appropriate for further processing. Secondly, they are utilized for fine grinding, which is essential for enhancing the fineness and the grade of the iron ore concentrate produced. This dual functionality makes ball mills an indispensable tool in the iron ore processing industry.

Choosing the right ball mill model and configuration is critical to improving iron ore beneficiation efficiency. This needs to be determined based on the characteristics of the ore and process requirements.

Therefore, Clirik recommends conducting mineral processing tests before purchasing. This helps determine the most suitable ball mill model. Ultimately, the iron ore processing process is optimized by reducing input costs.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly:

Share: