Calcite is a widely found mineral composed of calcium carbonate, known for its diverse crystal forms.The use of calcite powder has broad prospects, so what is its hardness and grinding process?

It has a Mohs hardness of 3, indicating that it is relatively soft and can be easily cut with a regular knife.

Due to its low hardness, calcite is not suitable for the manufacture of hard materials; however, it has excellent optical properties and is often used in the manufacture of optical devices.

Calcite has a relatively low hardness and is not suitable for the production of high-hardness building materials such as steel or concrete.

However, due to its high transparency, calcite is well suited for the production of materials such as glass, crystals and tiles, thus providing a more delicate and bright appearance to buildings.

glass

crystals

tiles

Calcite has excellent optical properties such as the birefringent effect, which makes it an ideal material for the manufacture of optical components such as polarizers and prisms.

polarizers

prisms

lens

As a natural mineral, calcite is both safe and not hard. The versatility of calcite allows it to play an important role in many industries such as construction, optics, beauty and medical care.

Calcite processing mainly includes three steps: crushing, sand making and grinding.

It has a Mohs hardness of only 3 and is relatively easy to break.

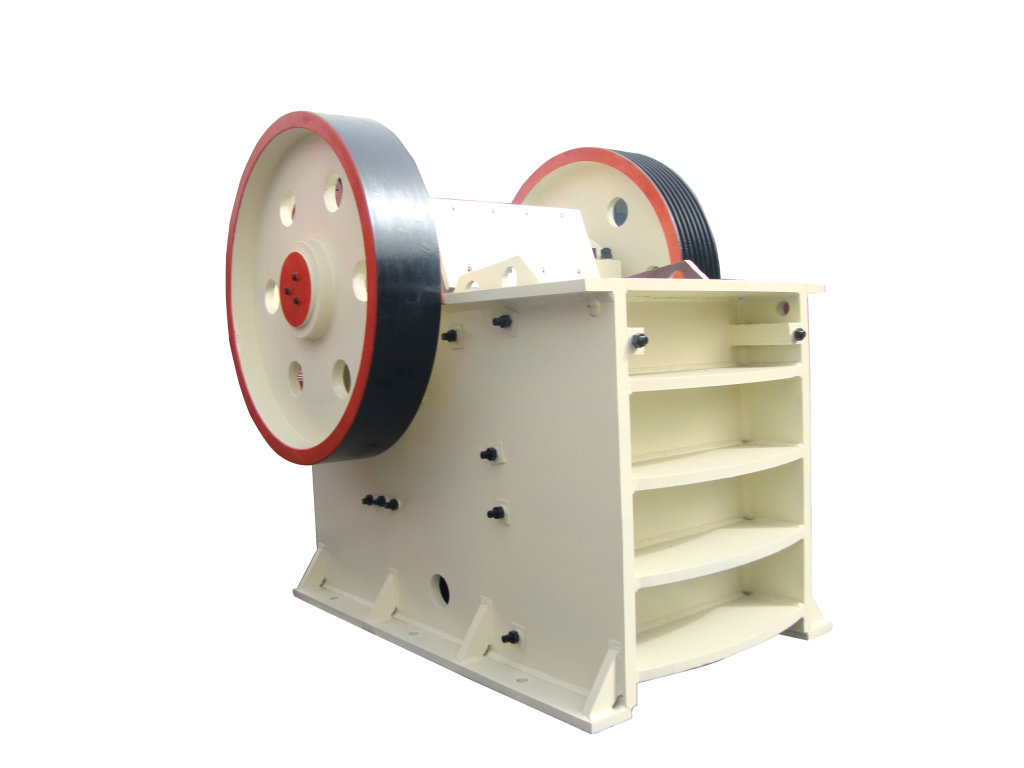

Preliminary Coarse Crushing

Calcite feedstock with a size of less than 400mm is uniformly fed into the vibrating feeder by the jaw crusher for initial coarse crushing treatment.

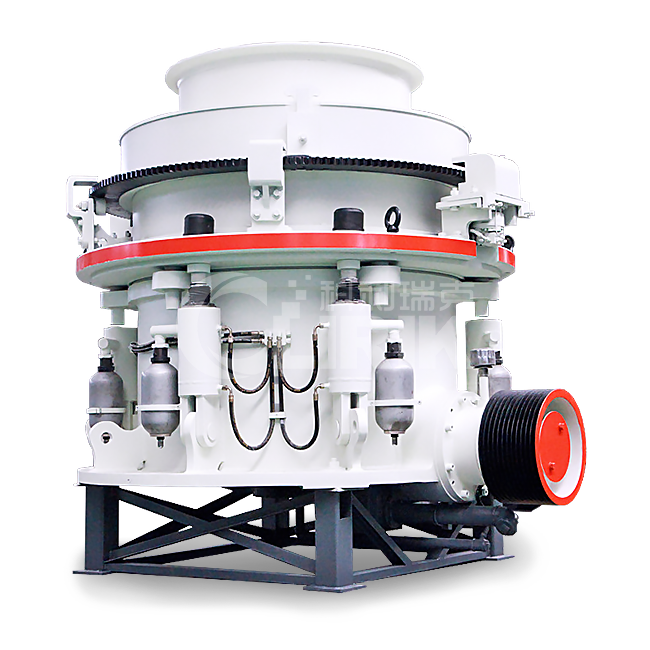

Secondary Crushing

After preliminary coarse crushing, calcite is sent to an impact crusher or cone crusher via a belt conveyor for secondary fine crushing treatment. The resulting calcite particles range in size from 5 – 50 mm.

Screening and Sorting

After the fine calcite is completed, it is sent to the vibrating screen for screening, thereby separating the different particle sizes and specifications of the product to meet your processing needs.

The crusher is suitable for crushing all kinds of soft and hard ores with compressive strength not higher than 320MPa, large crushing ratio, uniform product particle size, simple structure, low operating cost, and can achieve mass production.

The Cone Crusher is favored for calcite’s secondary fine crushing due to its reliability and stability. The Clirik Spring Cone Crusher, with its high swing frequency and optimized cavity, offers efficiency and energy savings, making it an ideal upgrade from traditional models.

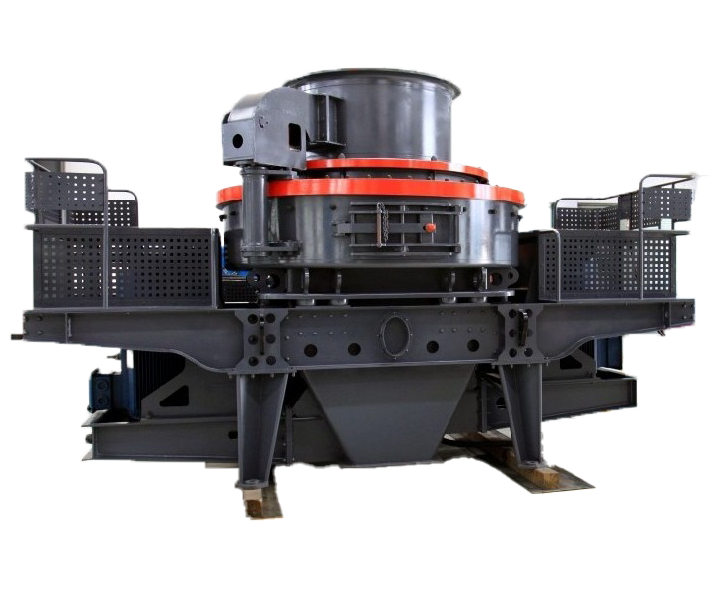

Impact crusher is mainly used for soft, medium and extremely hard crushing and shaping, suitable for calcite crushing, compared with the traditional equipment under the same power output increased by 30%, and stable operation, simple operation, the product is a cube, good particle shape.

Shaping

Calcite feedstock with a size of less than 400mm is uniformly fed into the vibrating feeder by the jaw crusher for initial coarse crushing treatment.

Secondary Crushing

The crushed calcite is fed into the sand making machine for particle shaping to produce sand that meets the specifications. The material that does not meet the particle size requirements will be sent back to the sand making machine for reshaping.

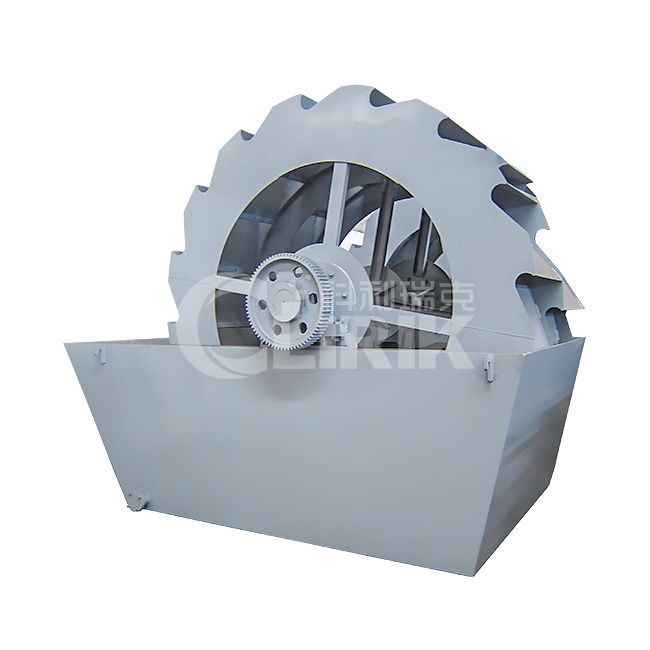

Washing

The calcite sand that meets the specifications is transported to the sand washing machine for cleaning, and then transported to the finished sand pile by the finished conveyor.

Impact crusher is mainly used for soft, mThe wheeled sand washing machine can clean and separate the stone powder soil in the sand, so as to improve the quality of the sand, and has the characteristics of saving water and energy, removing dust and removing impurities.

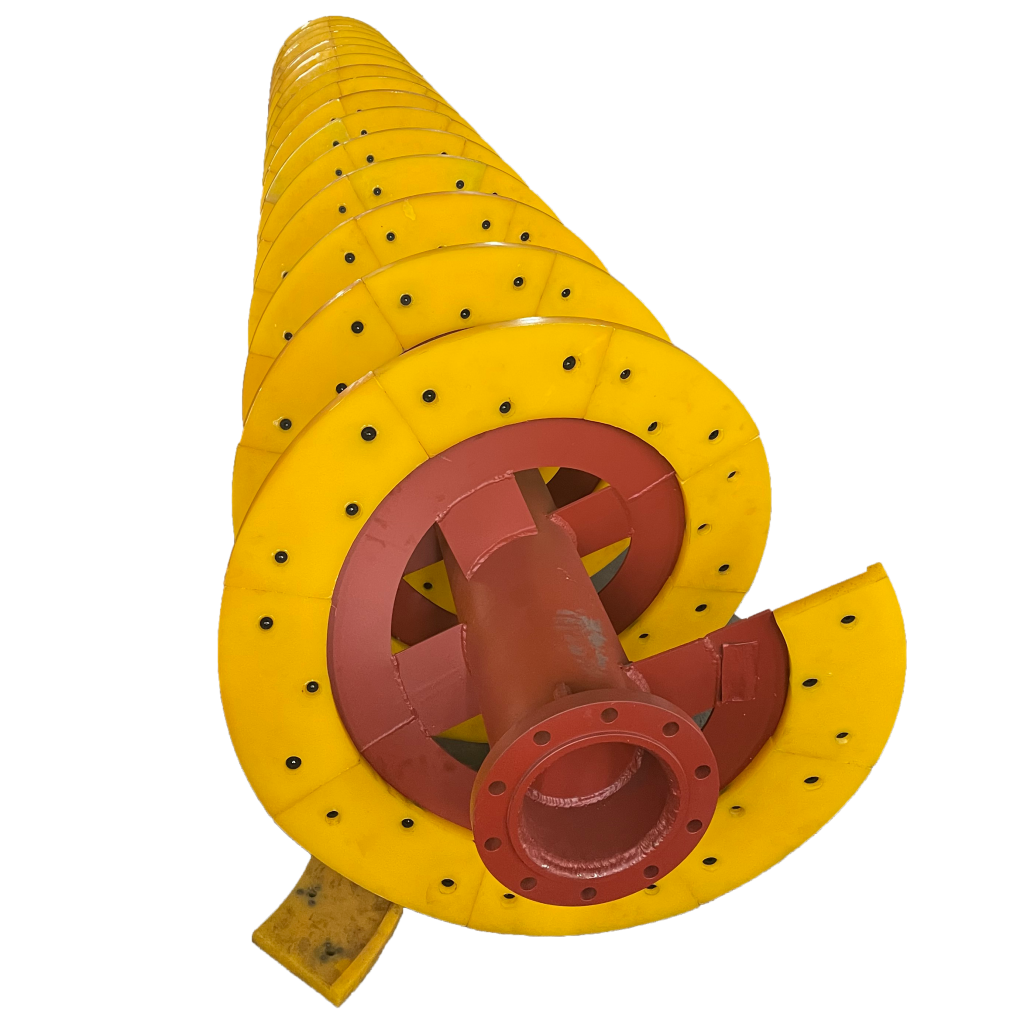

The spiral sand washing machine can clean and separate the soil and impurities in the sand and stone, with high sealing, and the adjustable transmission device can ensure the efficient cleaning and dehydration effect.

Grinding

The crushed calcite (≤30mm) is transported to the silo elevator through the bucket elevator, and then fed into the grinding chamber of the mill for grinding. Under the joint action of grinding roller and grinding ring, the material can be effectively crushed.

Grading

The ground powder is graded by the separator, and the unqualified powder is graded by the separator and returned to the host machine for re-grinding.

Collecting

The calcite powder conforming to the fineness flows into the collector with the wind, and is discharged through the powder discharge tube after collection.

CLRM Enhanced Roller Mill is suitable for crushing 80-425 mesh calcite fine powder, the machine output can be increased by more than 15%, the triple shock absorption technology ensures stable operation of the equipment.

The HGM Micro Powder Grinding Mill offers a wide range of product fineness, adjustable from 300 to 2500 mesh. It has a large output range of 0.5 to 30 tons per hour, catering to various production needs.

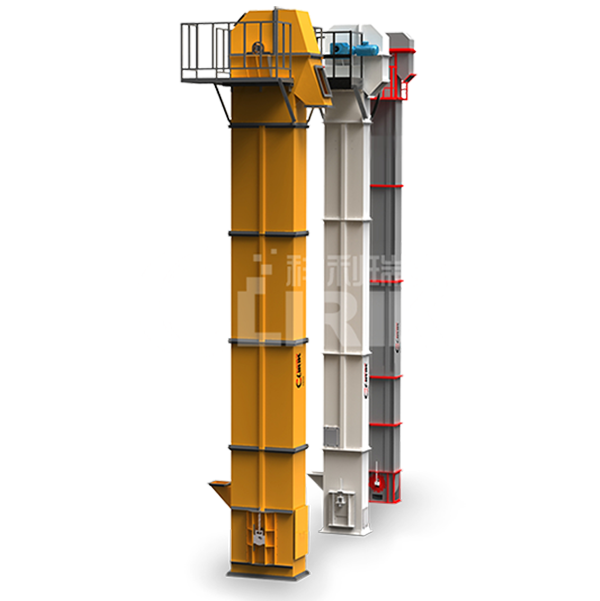

Bucket elevator is a widely used vertical conveying equipment, suitable for conveying powder, granular and small block of non-abrasive and abrasive small materials. The lifting capacity of bucket elevator is more than 30% higher than that of ordinary models.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly:

Share: