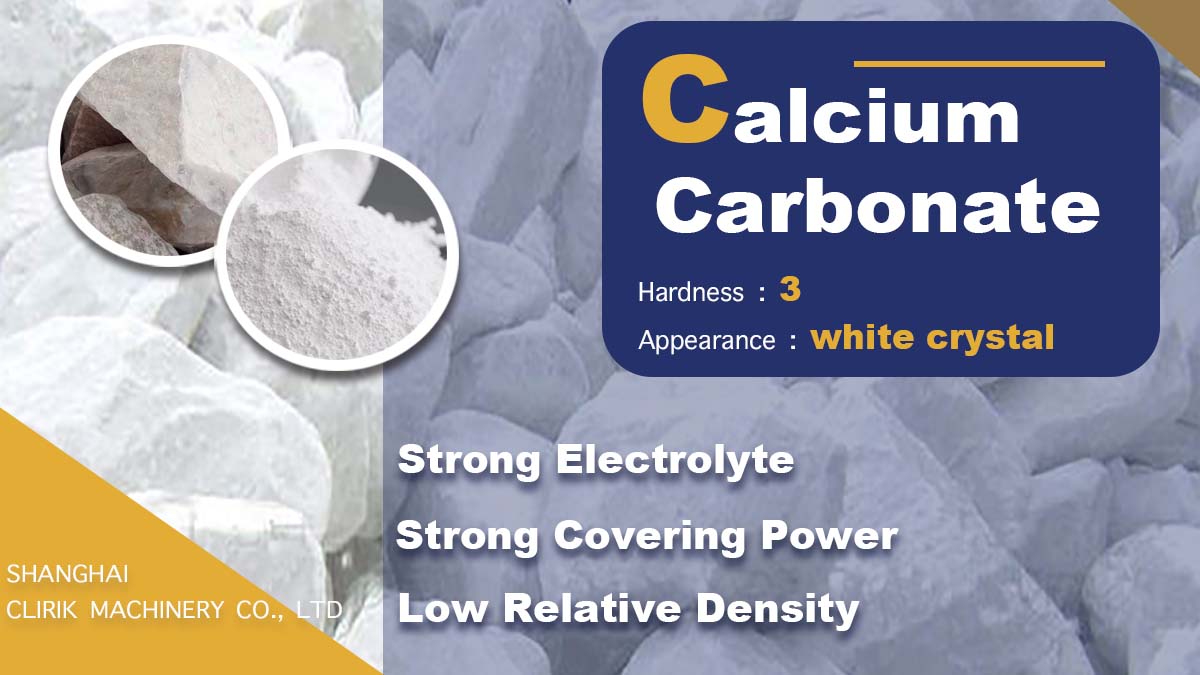

Calcium carbonate (CaCO3) is a white odorless, basically insoluble in water inorganic compounds, has a strong covering power and moisture absorption capacity of calcium carbonate powder ground from rocks containing CaCO3 is widely used, with high economic value.

Calcium carbonate as a building material can be used as a raw material for cement production, concrete filler and wall coating material.

Calcium carbonate can be used as a filler in plastics to increase the stiffness of the material.

Calcium carbonate serves as a nutritional supplement, offering a source of calcium to help manage conditions including osteoporosis and acid reflux.

Calcium carbonate functions as an agricultural amendment, raising the pH level in acidic soils and supplying calcium essential for plant growth.

Calcium carbonate acts as a coating and filler agent in the paper and pulp industry, enhancing paper’s brightness, opacity, and suitability for printing.

Crushing

The volume of newly mined calcium carbonate raw material is large and it is not easy to process directly. Calcium carbonate stones need to be treated by jaw crusher and hammer crusher, so that its particle size is reduced to 10-20 mm, in order to adapt to the feed requirements of the mill.

Grinding

The crushed small pieces of CaCO3 are lifted to the silo by a bucket elevator, which is then uniformly and quantitatively transported by a vibrating feeder to the mill for further crushing.

Classification

In order to ensure the uniform particle size of the pulverized powder, it is necessary to use an air classifier or vibrating screen to grade the calcium carbonate powder.

Collecting

The powder that meets the fineness requirement is carried by the airflow into the dust collector for separation and collection, then sent to the finished product silo for packaging, either by a powder tanker or an automatic baler.

The High Pressure Suspension Grinding Mill, developed by Clirik, is an upgraded version of the traditional Raymond Mill. It offers enhanced performance, with adjustable particle sizes from 50 to 325 mesh, making it an excellent choice for replacing conventional mills.

HGM Micro Powder Grinding Mill is mainly used for crushing and grinding medium and low hardness, Mohs hardness is less than or equal to 6 non-flammable and explosive brittle materials, the fineness of the finished product can be adjusted between 325-2500 mesh, successfully replacing the traditional air mill, ball mill complex procedures.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly:

Share: