The broken Chalk powder has a wide range of application scenarios and has high economic value. Then what are chalk’s mineral properties, crushing process and grinding equipment?

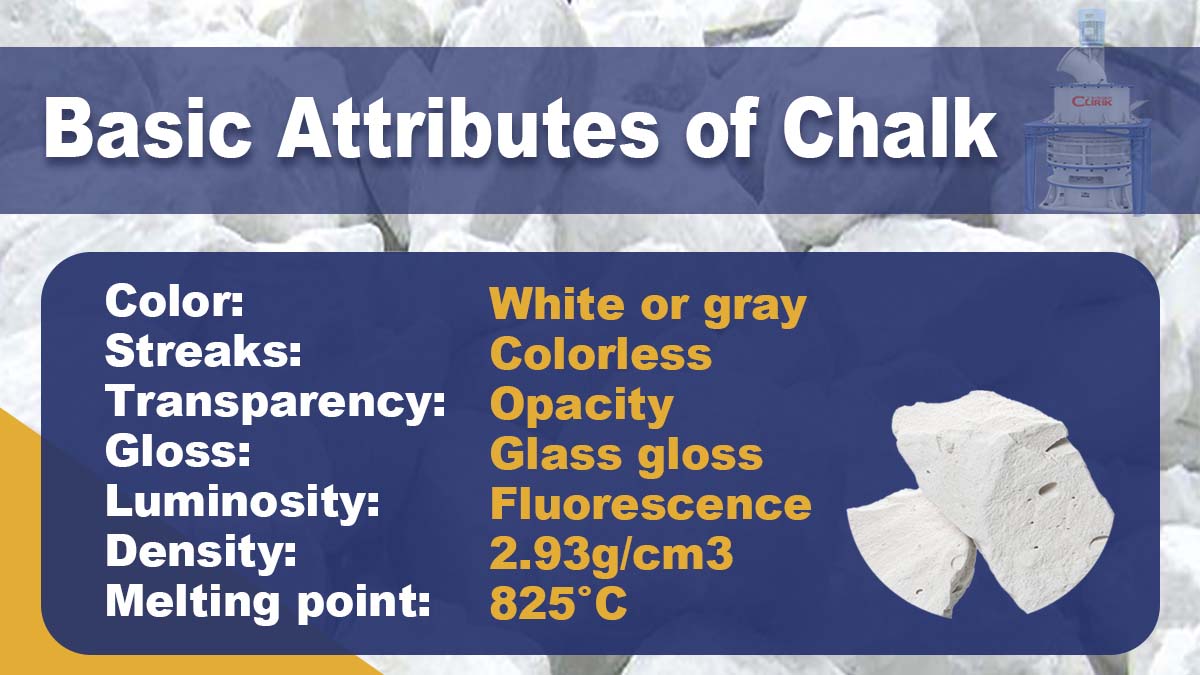

Chalk is a kind of loose limestone with the main chemical composition of CaCO3. It is formed by the accumulation of palaeontological remains. It is often produced in sedimentary rocks in a huge thick shape.

| Application Field | Description |

| Agriculture | Soil Regulation: Neutralizes acidic substances, raises soil pH, aids nutrient absorption. Yield Improvement: Enhances soil aeration and water retention, boosts crop yield and quality. |

| Industry | Cement Production: Mixed with clay and calcined at high temperatures to produce cement clinker, used for various types of cement. Chemical Industry Raw Material: Serves as filler, catalyst, or reaction medium, widely used in plastics, rubber, coatings, and other industries. |

| Environmental Protection | Wastewater Treatment: Neutralizes acidic substances in wastewater, reducing environmental pollution. Heavy Metal Removal: Binds with heavy metal ions in wastewater to form precipitates, effectively removing heavy metal pollution. |

| Daily Life | Chalk Making: Main ingredient for making chalk, widely used in schools and offices. Decorative Paints: As a filler in paints, enhances coverage, adhesion, brightness, and gloss of the paint. |

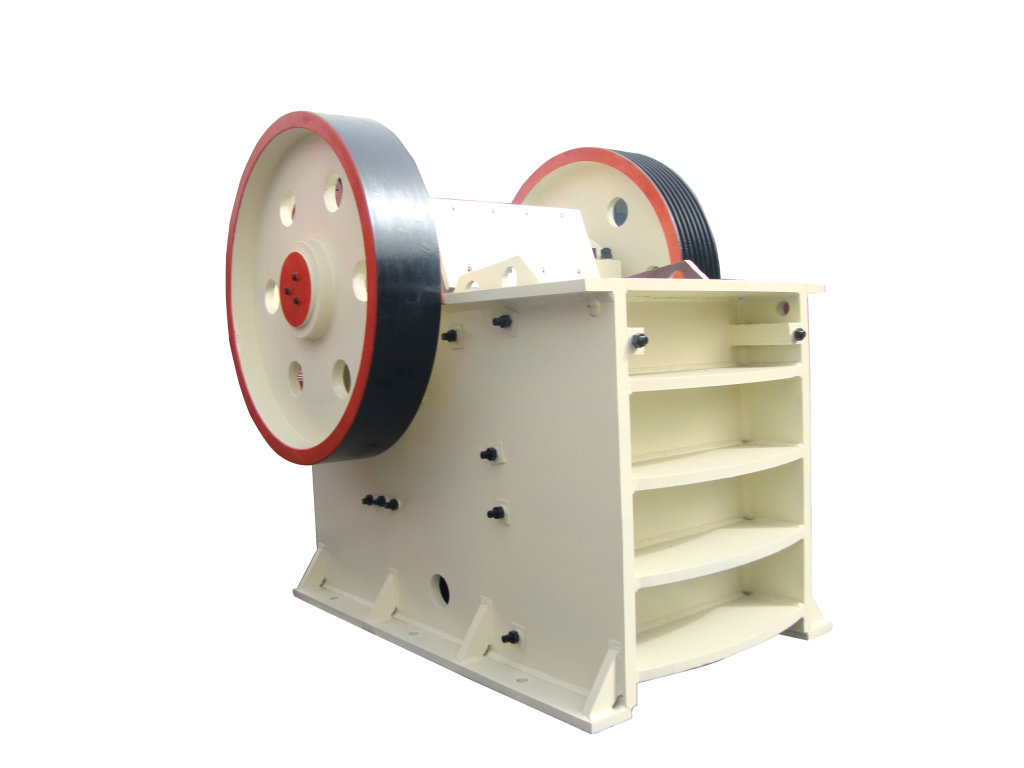

Crushing Stage

Large pieces of material are reduced to a manageable size (10-25mm) by a crusher, suitable for the ultrafine mill’s feed requirements.

Grinding Stage

Qualified particles are evenly and continuously fed into the mill’s grinding chamber via a conveyor and feeding system, where they are finely ground.

Classification Stage

The milled material is air-classified, with oversize particles returned to the mill for further grinding.

Powder Collection Stage

Fine powder is carried by air to the collection system, where it is separated from the air. The product is then conveyed to a silo for packaging by tanker or baler.

The Jaw Crusher is a common type of crusher used in chalk grinding production lines, primarily for the initial crushing of chalk materials to ensure they meet the size specifications needed for subsequent processing.

The HGM Micro Powder Grinding Mill boasts a production capacity 40% superior to pneumatic grinding, with adjustable fineness from 150 to 3000 mesh. It’s ideal for processing brittle, non-flammable, and non-explosive materials of low to medium hardness and a Mohs hardness below 6.

The CLRM Enhanced Roller Mill’s grinding structure is fully optimized, the output is increased by more than 15%, with triple shock absorption technology, stable operation of the equipment, and high fineness of the finished product.

The CLUM Ultrafine Vertical Roller Mills achieve a fineness of 400-3000 mesh, offer low vibration, high powder yield, 20% greater capacity than domestic peers, and 40% less energy use than ball mills.

Vibrating feeder is mainly used to evenly feed chalk into the receiving device. The equipment has the characteristics of small size, light weight, high working efficiency and low cost.

Bucket elevator is mainly used for vertical transportation of powder, granular and small block materials, which can meet the transmission mode required by different materials.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly:

Share: