White marble powder is widely used in the production of artificial marble, gypsum board and wall paint and other high-grade construction products. In addition, it is also used as a filler to improve the strength and durability of building materials.

Construction Industry

Dolomite powder can be used as a filler and reinforcing agent in rubber, plastics and coatings to improve the physical properties and durability of products. In addition, dolomite powder can also be used in the production of cosmetics, detergents and dyes.

Chemical Industry

As a reinforcing agent, dolomite powder can improve the hardness, strength and wear resistance of plastic products.

Plastics

Dolomite powder plays an important role in the field of environmental protection, it can be used as a water purification agent and wastewater treatment agent to remove heavy metal ions and organic pollutants in water.

Environmental Protection

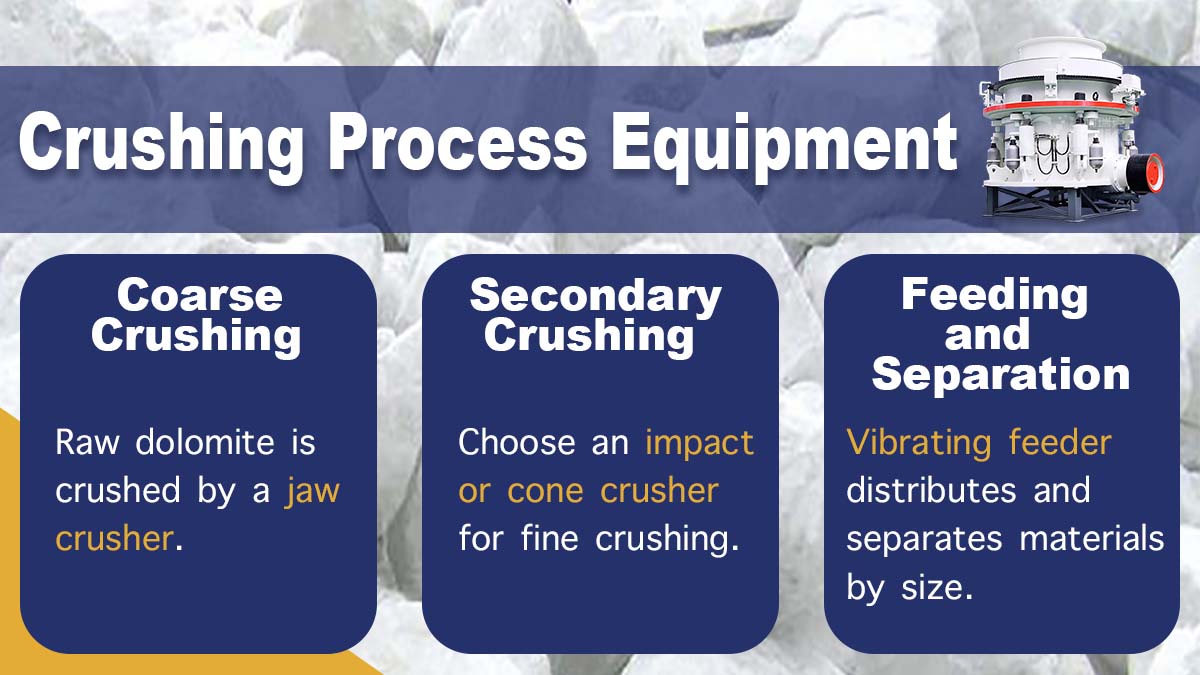

Coarse Crushing

Large pieces of dolomite raw materials through the vibration feeder evenly into the jaw crusher, to achieve preliminary crushing.

Secondary Fine Crushing

After the first crushing of the material by the belt conveyor to the cone crusher for secondary crushing, and then through the impact crusher to complete the third level of fine crushing.

Classification Screening

The dolomite material after fine crushing is sorted through the vibrating screen, the crushed qualified material is discharged through the sieve, and the unqualified material is returned to the crushing link to achieve cyclic treatment.

Product Size Customization

The dolomite material after fine crushing is sorted through the vibrating According to the demand, the final product size adjustment and combination.

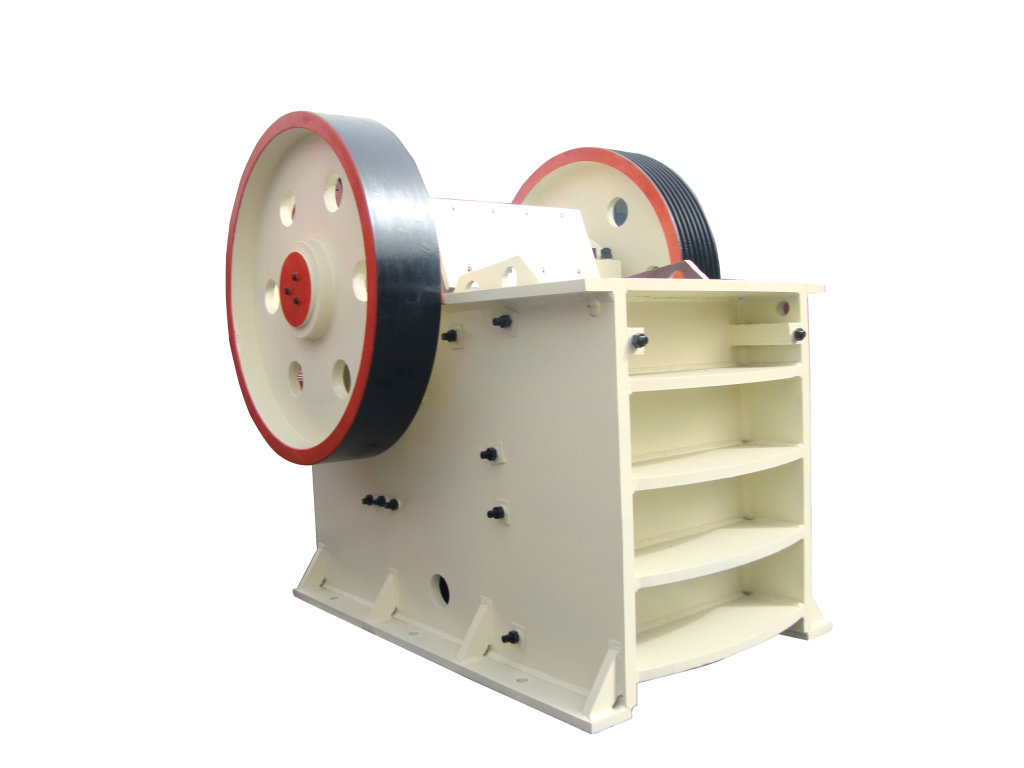

The jaw crusher is primarily utilized for crushing ores with a compressive strength of up to 320MPa, offering large reduction ratios, uniform particle sizes, and a simple design. It is suitable for both fine and coarse crushing tasks.

Jaw crusher because of its wide range of applications and efficient performance, in the dolomite coarse crushing stage plays an important role, its characteristics include:

(1) The crushing chamber design is deep, which can ensure that the material is completely broken, thereby improving the output and efficiency.

(2) The shape of the broken dolomite is regular, which helps to reduce dust emissions in the production process.

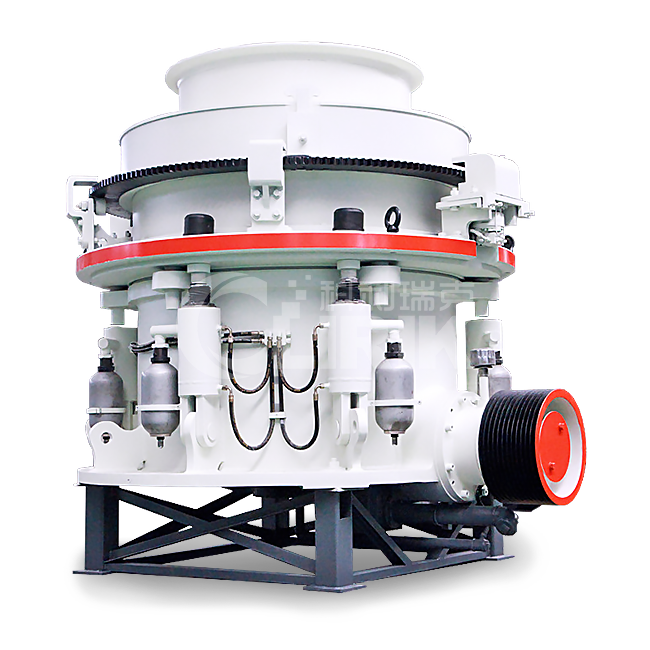

The Cone crusher has the characteristics of high reliability, good stability and multi-type crushing chamber, which is suitable for the second fine crushing operation of dolomite.

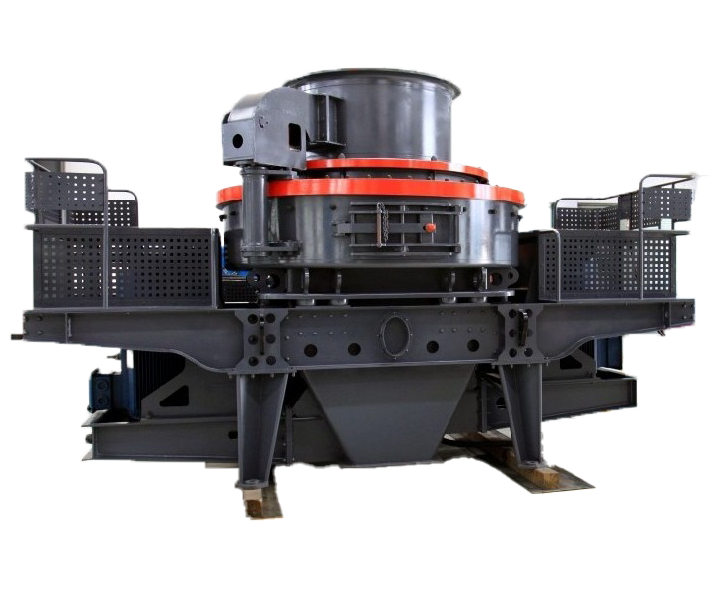

The vertical impact crusher is mainly used for soft or medium hard and extremely hard crushing and shaping, and its production capacity can be increased by up to 30% compared to traditional equipment with comparable power.

As the final step of dolomite processing, grinding plays a decisive role in product quality. Therefore, we pay special attention to the process control of this link, We can provide you with HGM Micro Powder Grinding Mill, CLRM Enhanced Roller Mill, CLUM Series Ultrafine Vertical Roller Professional milling equipment such as Mills to ensure that the final product meets the expected quality standards.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly:

Share: