Ore is one of the most important raw materials in the construction industry. The consumption of mineral raw materials required for construction accounts for 90% of the output of non-metallic minerals. In particular, limestone consumes billions of tons every year. In recent years, environmental policies have grown stronger. This has increased interest in the lime grinding industry.

Lime is widely used in various sectors. It plays a role in construction, metallurgy, and agriculture and forestry. Additionally, lime is crucial in environmental protection. It helps in treating sewage and in desulfurizing flue gases.

Lime deep processing transforms limestone into valuable lime. Indeed, high-heat calcination converts limestone into quicklime, primarily calcium oxide. Furthermore, when quicklime reacts with water, it forms slaked lime, mainly calcium hydroxide. To satisfy market needs, Clirik has created an eco-friendly, large-scale calcium hydroxide production line. Additionally, this intelligent lime grinding production line, which is designed to boost industry upgrade, has been successfully implemented, thereby enhancing the lime industry’s quality development.

Calcination

The selected limestone is sent to the environmentally friendly lime kiln and calcined at high temperature to produce quicklime.

Grinding

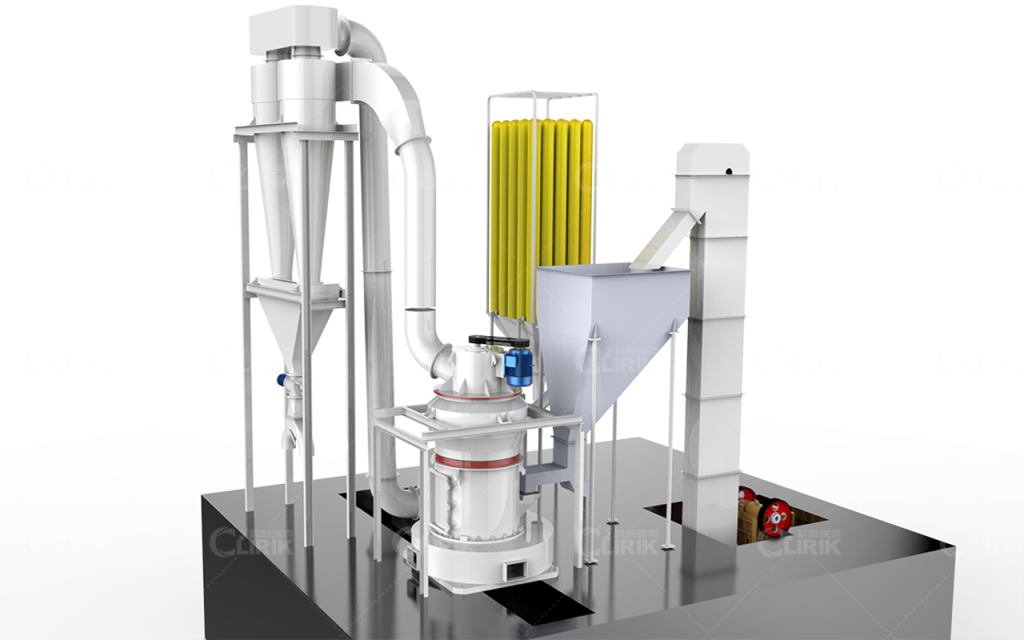

Quicklime can be directly crushed by Raymond Mill or Vertical Roller Mill, processed from block to powder, and directly supplied to the market.

Digestion

Quicklime can be further processed and sent to the calcium hydroxide production line. After a five-stage digestion process (1st stage pre-treatment – 3rd stage homogenization – 1st stage pulverization), it becomes slaked lime.

Powder selection + Collection

The digested slaked lime is screened by the powder selection machine, and after collection, it is the fine calcium hydroxide product, and the excess slag is discharged.

Grinding + Classification + Collection

The digested slaked lime can also be crushed by Raymond mill, screened by the classifier after the fineness is qualified, and then collected in the dust collector to obtain ordinary calcium hydroxide products.

Clirik’s lime deep processing process not only increases the added value of lime products, but also helps to promote the high-value development of the lime industry.

Share: