In the field of modern energy technology, lithium batteries have become an indispensable energy source for many electronic products, electric vehicles, etc. due to their high energy density, long life and environmental protection.

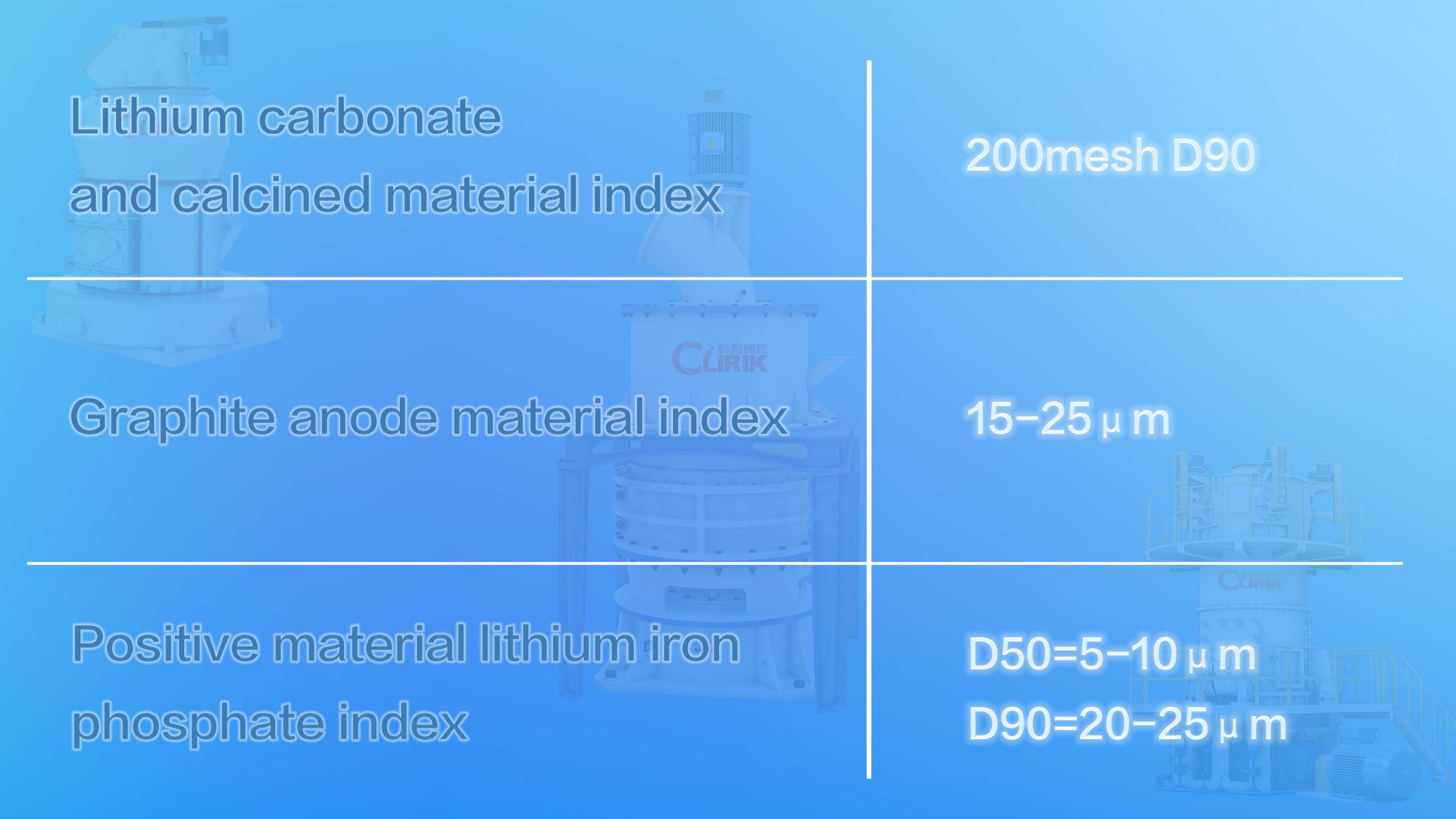

Ternary lithium battery powder contains a large amount of valuable metals such as nickel, cobalt, and lithium, has high recycling value, can be used to produce new battery materials, reduce costs, and reduce environmental pollution, and has broad application prospects.

The production process of lithium battery raw materials, especially grinding technology, plays a vital role in the overall performance of the battery.

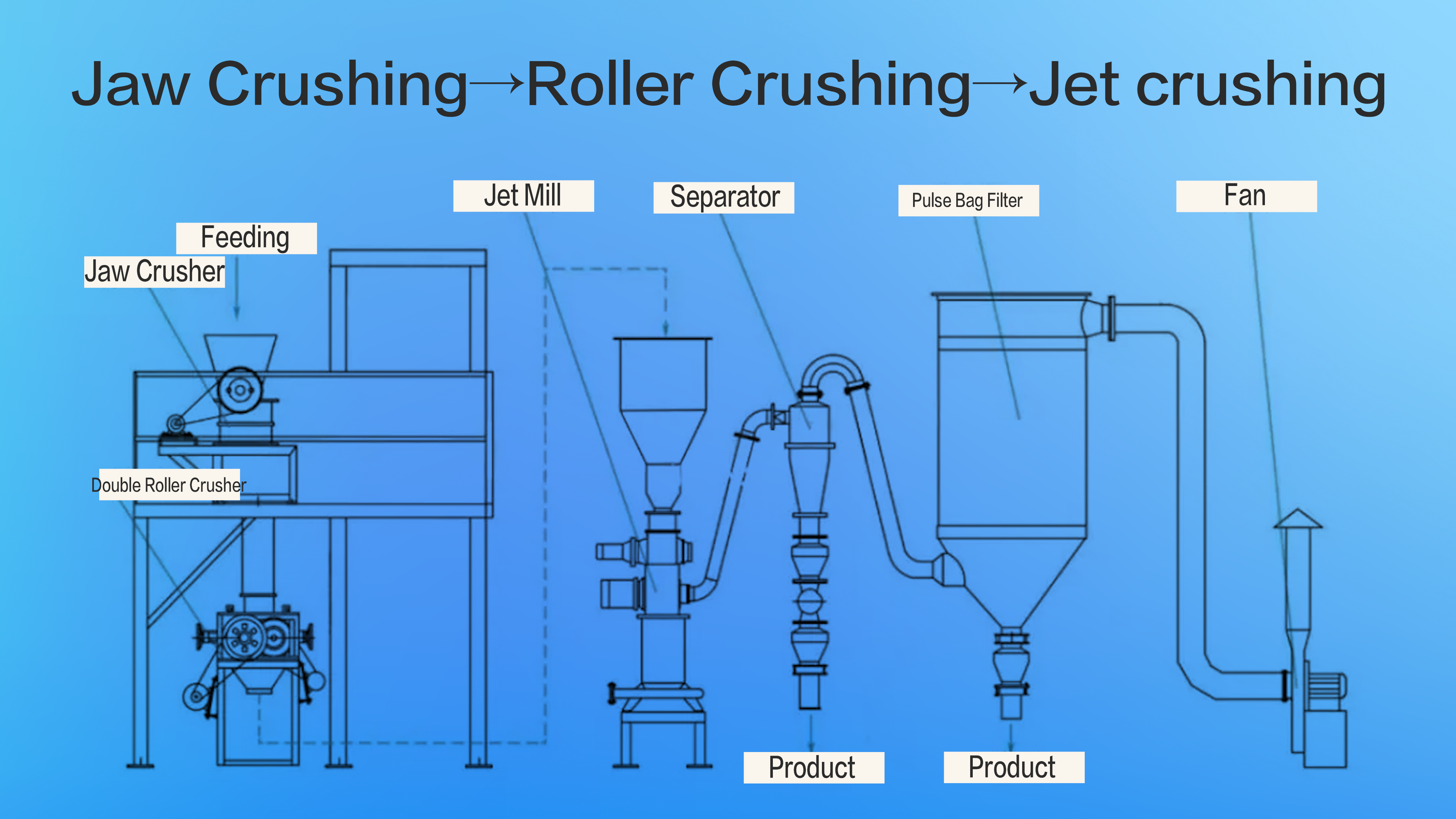

The Jaw Crusher uses a kinetic extrusion crushing method. The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft.

As the motor rotates continuously, the movable jaw of the crusher periodically crushes and discharges materials to achieve batch production.

Adventure:High crushing ratio, uniform particle size, simple structure, reliable performance, easy operation and maintenance.

The Double Roller Crusher drives the rollers through the motor, and the rollers rotate in relative directions. When crushing materials, the materials pass through the rollers from the feed inlet, are crushed by rolling, and the crushed products are discharged from the bottom of the bottom frame.

Adventure:High crushing ratio and low noise, overload protect and reliable, high efficiency and uniform particle size.

The Jet Crusher uses high-speed air flow as the power and carrier, and converts the air flow beam formed by compressed air into velocity energy through the nozzle in the grinding chamber.

Adventure:Low energy consumption, high fineness, simple structure, uniform product particle size.

Clirik Lithium electric material grinding process achieves high efficiency and low emissions. It is well-known in the crushing and grinding industry for its uniform and high-quality finished product particle size. It can provide you with a cost-effective lithium battery grinding solution.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly:

Share: