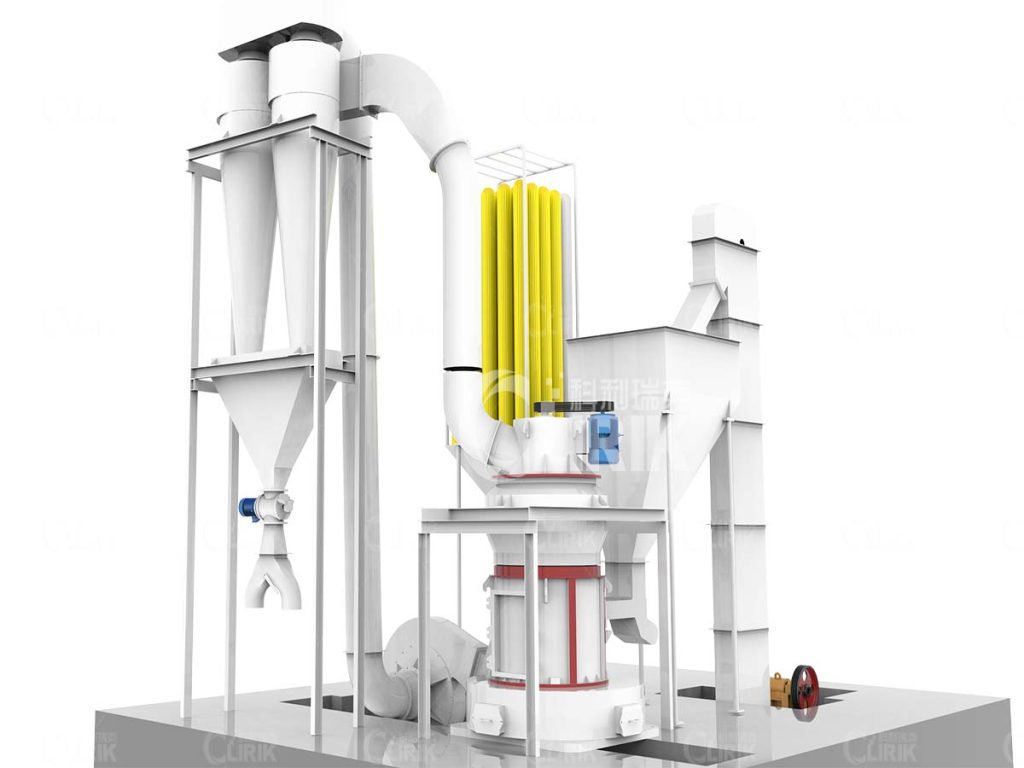

Brief Introduction

Our Air Conveying System, with a roots blower, excels in short-distance powder transport, reaching 300m horizontally and 30m vertically. It handles fine, light powders at temperatures up to 250°C and offers a 60-ton hourly capacity for single or multi-point feeding.

Features

Efficiency and Flexibility

The adjustable pipe arrangement and fully sealed system enhance production workflow efficiency and support various operation processes, including mixing and crushing, while facilitating long-distance transport from multiple points.

Environmental and Quality Control

Minimizing airborne dust and preventing material degradation from dampness, contamination, or damage ensures environmental protection and maintains material quality.

Maintenance and Automation

With minimal moving parts, the system is easy to maintain and automate, reducing downtime and labor costs.

Cost-Effective Operation

High transport efficiency and the ability to handle multiple processes in one system reduce overall production costs, including packing, loading, and unloading.

Safety and Chemical Compatibility

Suitable for unpredictable chemical materials, the system ensures safety through inert gas transportation and prevents unwanted mixing.

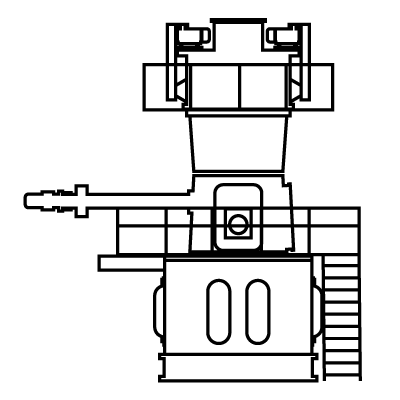

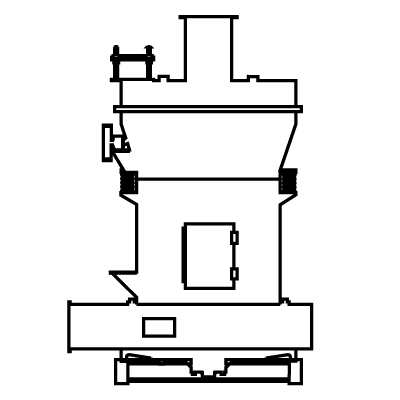

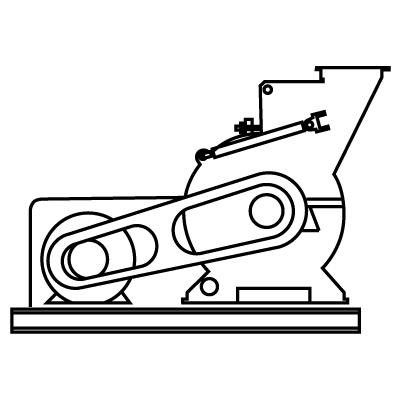

Working Principle

Using an electric rotary feeder as the feeding device, materials are evenly introduced into the mixing chamber.

Simultaneously, the roots blower generates high-speed airflow, which accelerates the material into the acceleration chamber.

The suspended flow then moves through the conveying pipeline into the silo.

Upon filtration and separation, the powder settles into the silo while the gas is released into the atmosphere.

Specification

| Model | CLXB-75 | CLXB-100 | CLXB-150 | CLXB-200 | CLXB-250 |

| Capacity (t/h) | 1-4 | 3~9 | 10~15 | 15~20 | 18~25 |

| Blast capacity (m3/min) | 3~9 | 9~20 | 20~36 | 36~50 | 50~70 |

| Inlet pipe diameter | DN100 | DN133 | DN125/DN159 | DN219 | DN273 |

| velocity in pipe (m/s) | 13~16 | ||||

| Pressure (kpa) | ≦98 | ||||

| Body material | cast iron, cast steel, stainless | ||||

| Motor (kw) | 3-15 | 15-30 | 35-65 | 70-90 | 90-110 |

Other Main Products

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: