Brief Introduction

The Clirik Bucket Elevator is a vertical conveying equipment widely used for conveying powders, granules, and small lump materials that do not require excessive friction or abrasion (material temperatures below 250°C).

Application

The Bucket Elevator finds applications in industries such as coal, cement, gravel, sand, fertilizer, and food processing.

Features

1. Increased Capacity

Offers a capacity 1.5 times greater than that of comparable HL bucket elevators with the same bucket width.

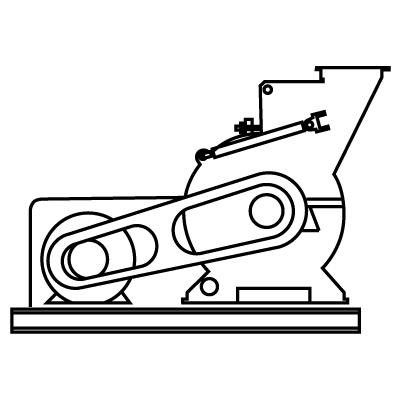

2. Enhanced Sprocket Design

The elevator employs a modular sprocket system with high-strength bolts, enabling quick and cost-effective rim replacements and enhancing maintenance efficiency.

3. Robust Tensioning System

The lever tensioning device provides automatic tensioning for smooth operation and consistent chain tension, preventing slippage.

4. Stable Performance

Provides stable lifting height, reliable operation, low noise levels, and ease of maintenance.

5. Improved Conveying Capacity

Achieves a 30% increase in conveying capacity compared to standard models.

6. Durable Drag Components

Equipped with high-strength, low-alloy steel chains that undergo precise heat treatment for exceptional tensile strength and wear resistance, ensuring extended operational lifespan.

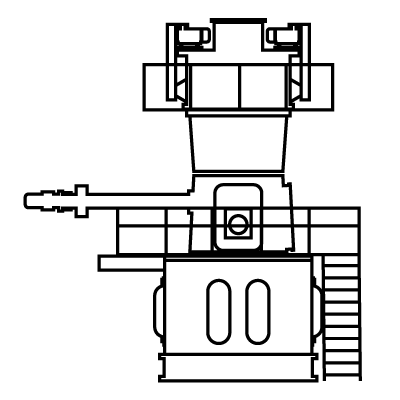

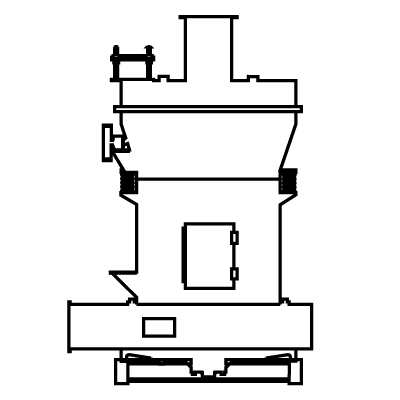

Working Principle

Detailed description

· The head wheel, or driving wheel, is the central component of the elevator, with a feed inlet for material intake and a discharge outlet for material release.

· Material is fed into the elevator at the base through a chute, where it is captured by hoppers and lifted along the conveyance chain.

· Once it reaches the top wheel, the material is deflected downwards into the discharge outlet, ensuring a smooth delivery to the target destination.

· This entire operation is enclosed within the framework, significantly reducing dust dispersion.

The drag assembly utilizes durable alloy steel chains and a sprocket wheel with a composite rim for enhanced durability and easy maintenance.

Gravity-actuated tensioners in the lower section maintain chain tension, avoiding slippage and ensuring adaptability.

This system protects the lower shaft and components from damage during hopper blockages.

Main Specification

| Type | TH200 | TH315 | TH400 | ||||

| Hopper Type | ZH | SH | ZH | SH | ZH | SH | |

| Capacity (m3/h) | 17.87 | 28.6 | 35 | 59 | 58 | 93 | |

| Hopper | volume (L) | 1.5 | 2.4 | 3.75 | 6 | 5.9 | 9 |

| Interval (mm) | 500 | 512 | 512 | ||||

| Chain | steel diameter x pitch (mm) | φ14*50 | φ18*64 | φ18*64 | |||

| breaking strength (KN) | ≥190 | ≥320 | ≥320 | ||||

| Speed (r.p.m) | 63.22 | 44 | 37.6 | ||||

| Input size (mm) | 25 | 35 | 40 |

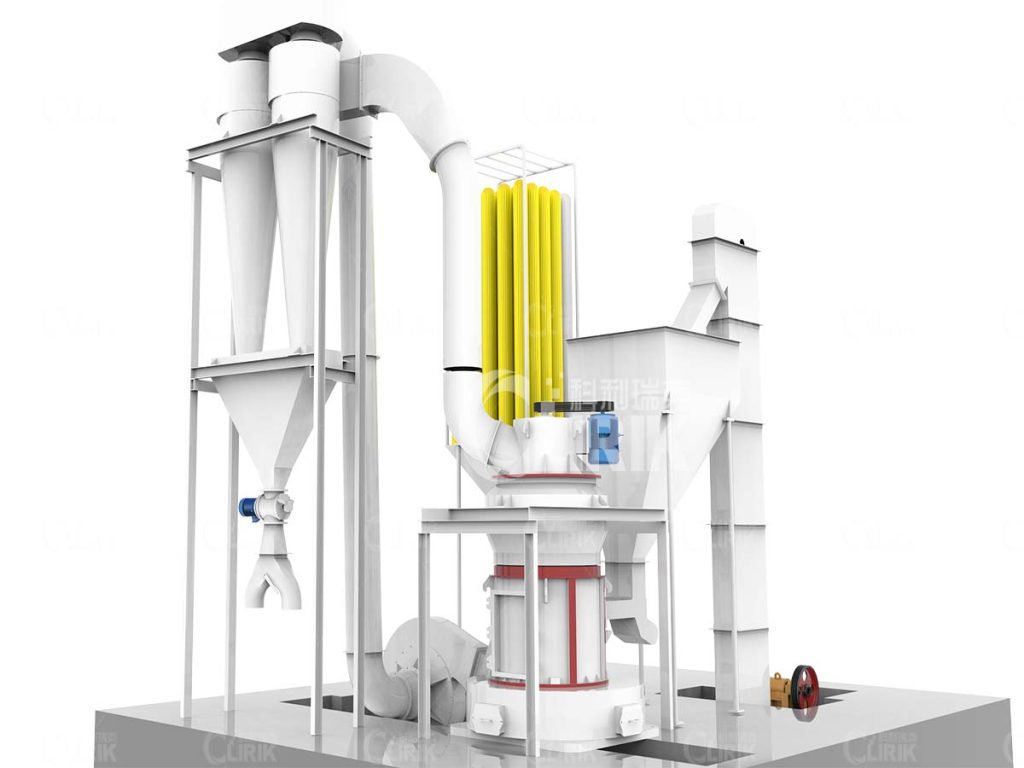

Other Main Products

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: