Brief Introduction

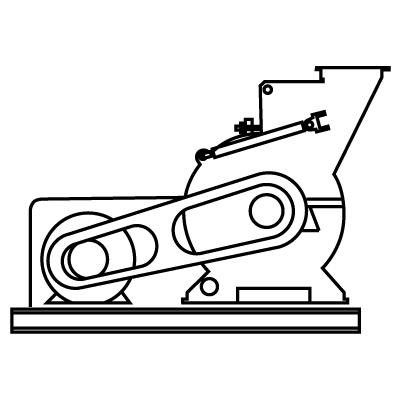

The Clirik Cabinet Hammer Crusher offers a spacious feeding inlet, making it ideal for processing large materials with sizes ranging from 450-1400mm into smaller sizes below 100mm.

Scope and

Application

The Clirik Cabinet Hammer Crusher widely utilized in mining, cement, construction materials, and chemical industries, it effectively crushes materials with a compression strength not exceeding 200MPa, such as limestone, rock, plaster, and coal gangue.

Working Features

1. Large Feeding Inlet

Accommodates big material sizes, ensuring high throughput.

2. High Crushing Efficiency

Achieves a high reduction ratio with uniform particle size output.

3. Adjustable Output Size

Allows for customization of the final product size.

4. Durable Components

Features robust hammers and a turnable cabinet for easy maintenance.

5. Single-stage Crushing

Performs coarse and medium reduction in one pass, simplifying the crushing process.

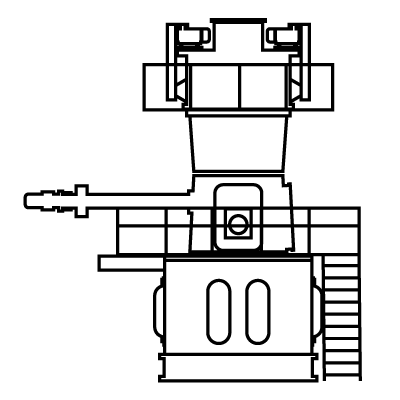

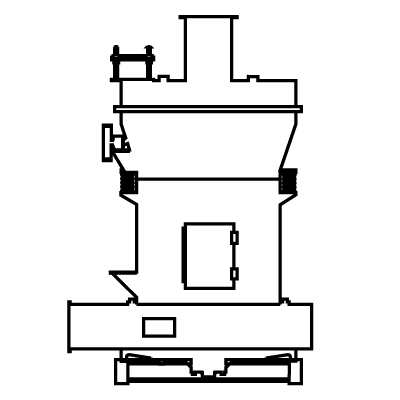

Working Principle

High-Speed Hammer Motion

· Inside the Clirik Cabinet Hammer Crusher, the motor drives the hammers to move in a high-speed circular motion.

Initial Material Accumulation

· Large materials are fed into the crusher and accumulate on a special shelf within the crusher box.

Hammer Crushing Process

· The raw materials are crushed into smaller pieces by the impact of the rapidly moving hammers.

Two-Stage Crushing Mechanism

· Unqualified pieces are further crushed by the impact against an impact plate, which is set to interact with the tangent of the hammers’ circular motion.

Final Screening and Discharge

· The end product is screened to ensure uniform particle size before being discharged from the machine.

Specification

| Model | PCX600 | PCX800 | PCX1000 |

| Feeding Size (mm) | 550 | 780 | 780 |

| Rotor Shaft Speed (r.p.m) | 600-800 | 650-750 | 650-750 |

| Finished Size (mm) | ≤50 | ≤50 | ≤50 |

| Capacity (t/h) | 30-50 | 40-80 | 50-100 |

| Total Weight (ton) | 40-55 | 75-90 | 90-110 |

| Total Weight (ton) | 4.2 | 4.8 | 6.5 |

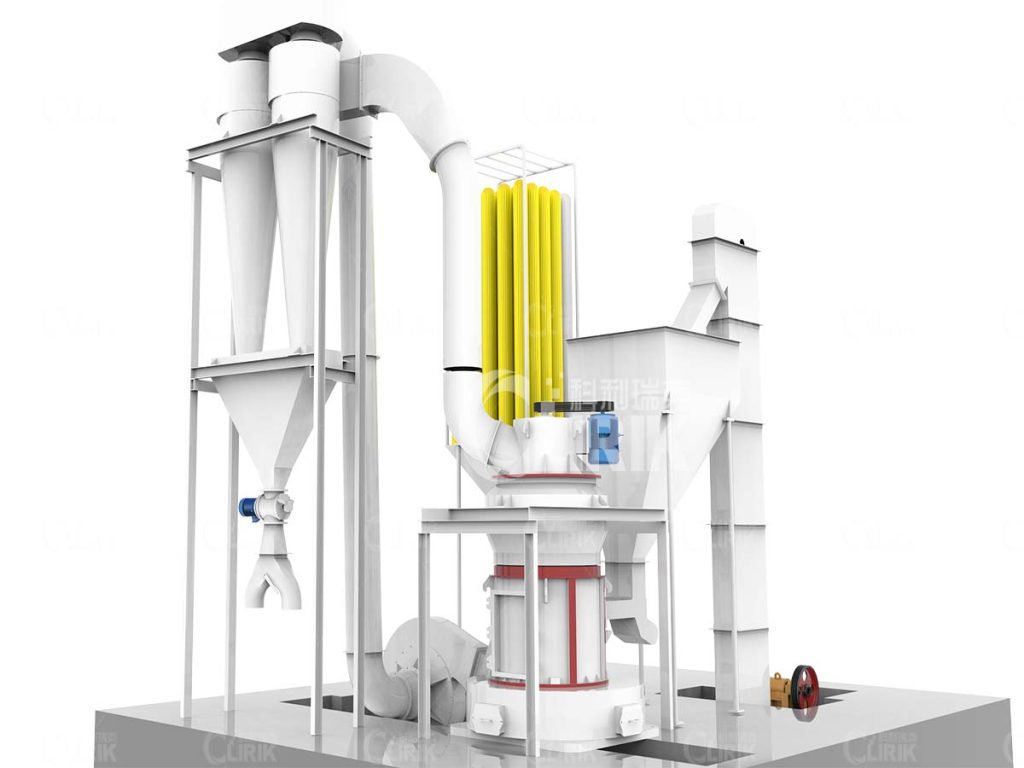

Other Main Products

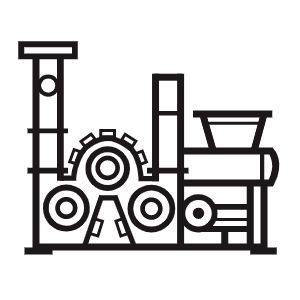

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

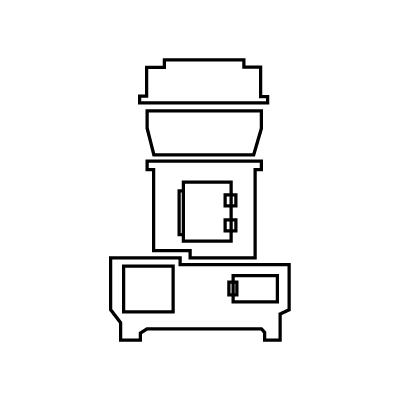

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: