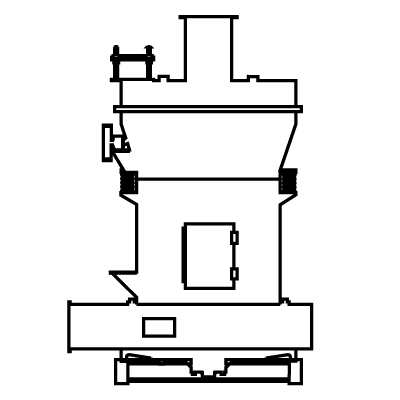

Brief Introduction

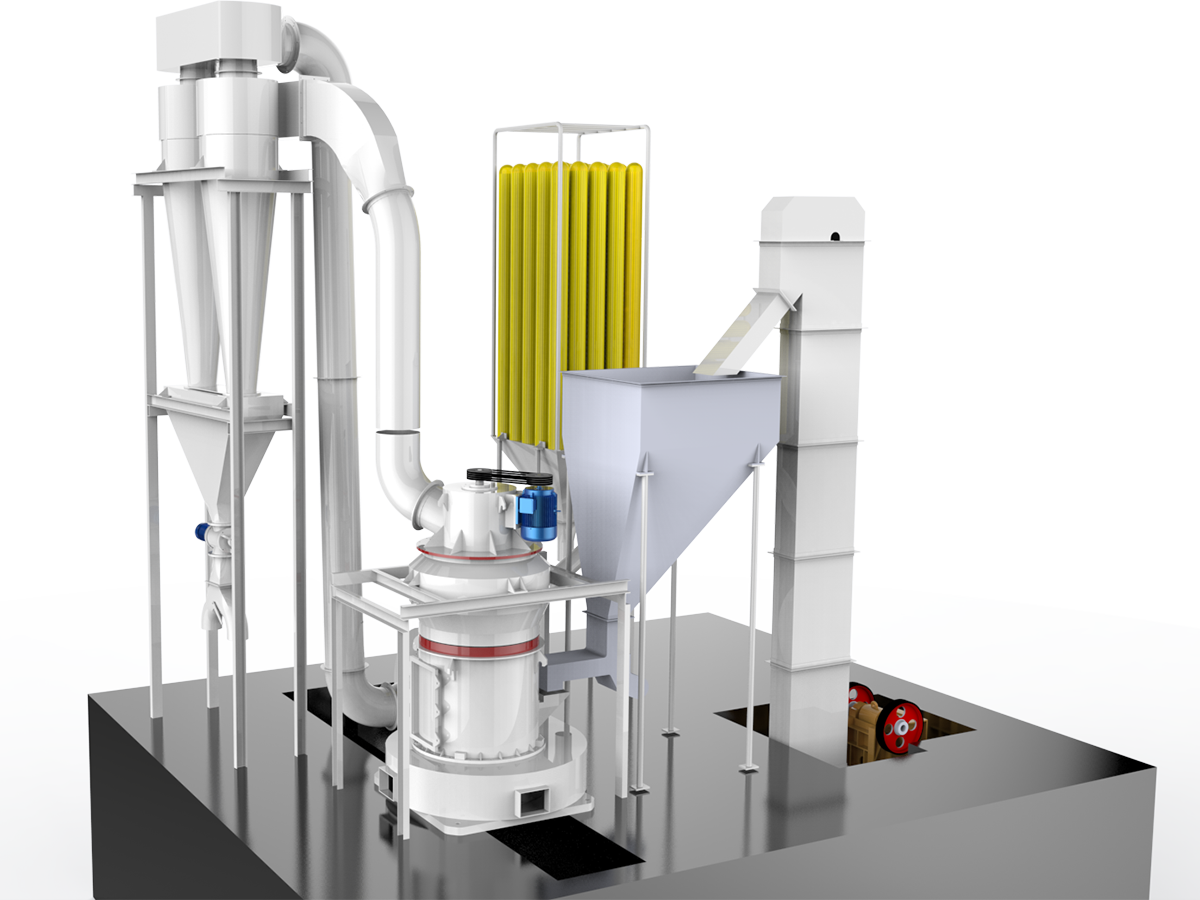

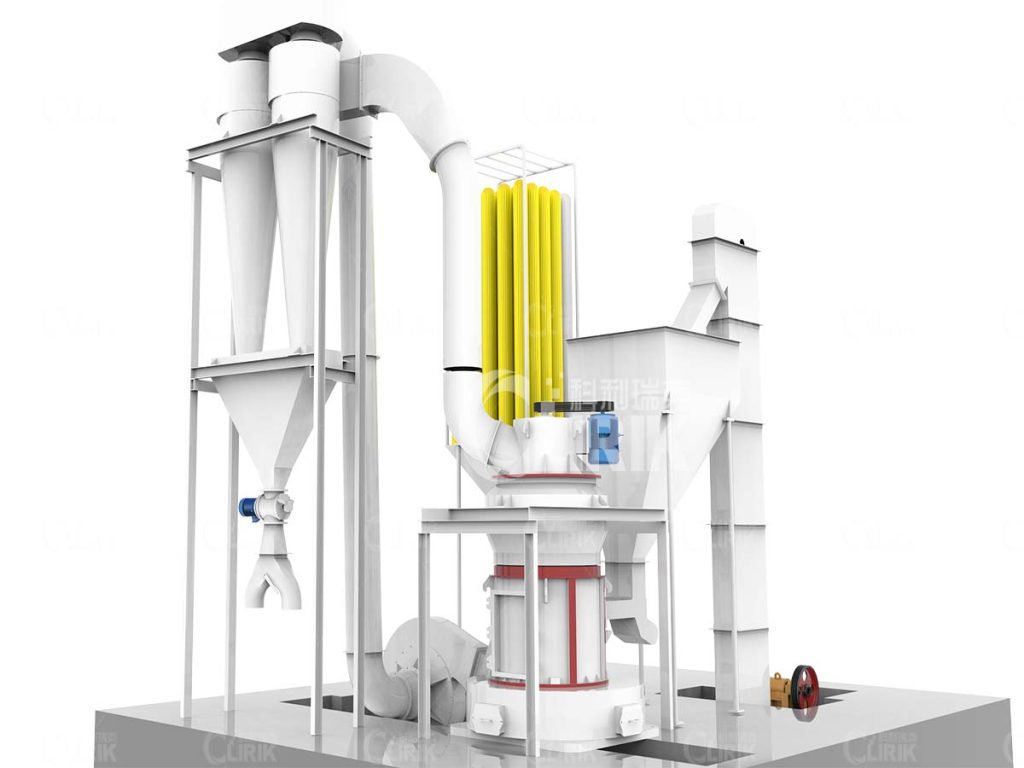

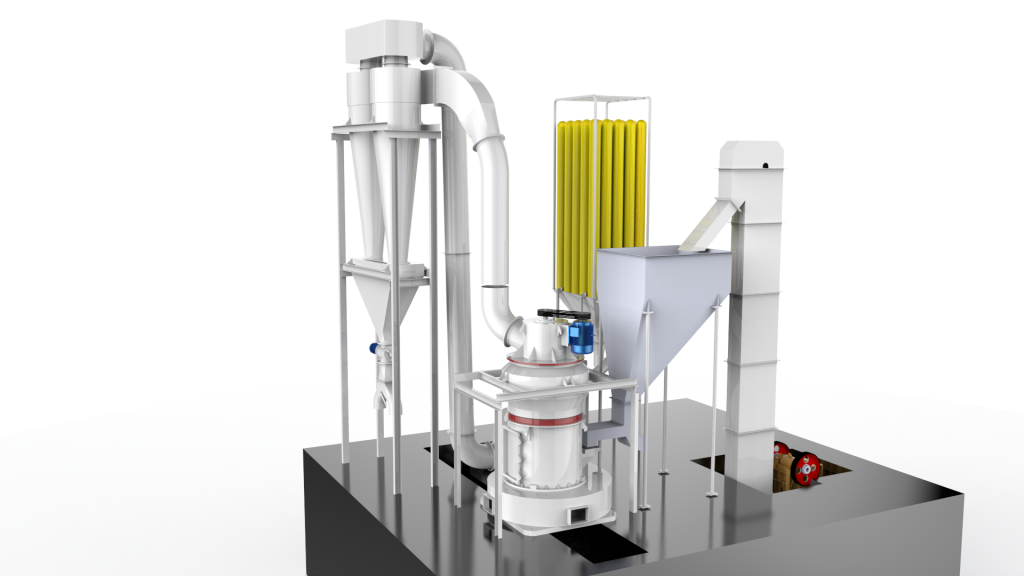

Our CLRM Enhanced Roller Mill is adjustable, capable of producing powder from 80 to 500 mesh, and is suitable for grinding materials with a Mohs hardness of less than 6.

Scope and Application

The output fineness of the powder can be tailored from 80 to 500 mesh. It processes a wide array of materials such as quartz, feldspar, barite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal, and more, encompassing approximately 400 different substances.

Working Principle

1. Material Preparation

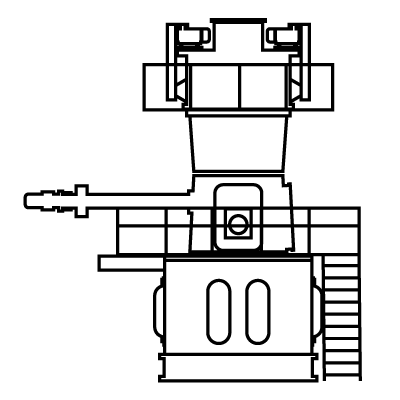

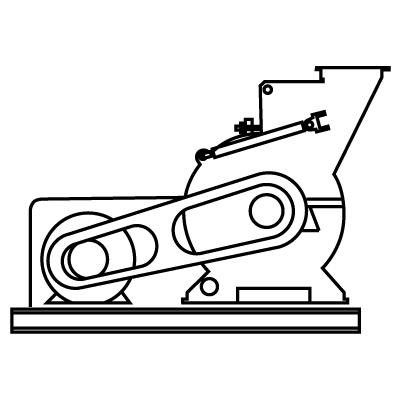

Large materials are crushed to the desired size by a jaw crusher and then transported to a hopper by a bucket elevator. A vibrating feeder evenly and continuously feeds the material into the main grinding unit.

2. Powder Processing and Classification

The pulverized powder is carried by air from the blower to a classifier, where particles meeting the fineness specifications are channeled into a cyclone for separation and collection. The finished product is discharged through an outlet valve.

3. Air Recirculation and Collection

Air is drawn back into the blower through a return duct at the top of the cyclone, completing a sealed circulation system that operates under controlled positive and negative pressure.

Advantages

● Enlarge the fineness range 80-425 mesh.

● Optimize the grinding structure, enhance the capacity over 15%.

● The triple shock absorption technology ensures stable operation of the equipment.

● Compact structure, low investment and maintenance.

Power Parameter

| Model | Roller Qty (pcs) | Roller Size (mm) | Ring External Dia (mm) | Ring H (mm) | Main Shaft Speed (r/min) | Feeding Size (mm) | Mesh | Motor (kw) | Capacity (t/h) |

| CLRM9720 | 3-4 | Φ320*200 | 1077 | 200 | 145 | <20 | 80-500 | 45*15*37 | 1-7 |

| CLRM1280 | 3 | Φ370*240 | 1280 | 240 | 125 | <20 | 80-400 | 75*15*55 | 2-12 |

| CLRM1300 | 4 | Φ410*280 | 1390 | 280 | 112 | <20 | 80-400 | 110*22*90 | 3-15 |

| CLRM1620 | 4 | Φ450*300 | 1620 | 300 | 102 | <20 | 80-400 | 160*30*132 | 5-20 |

| CLRM1700A | 4 | Φ510*300 | 1700 | 300 | 102 | <30 | 80-325 | 185*37*160 | 6-25 |

| CLRM1900A | 4 | Φ600*300 | 1900 | 300 | 92 | <35 | 80-325 | 250*45*220 | 8-32 |

| CLRM2200 | 4 | Φ650*300 | 2200 | 300 | 82 | <35 | 80-325 | 315*55*280 | 16-40 |

Other Main Products

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: