Brief Introduction

The CLUM series ultrafine vertical roller mill is widely used in industries like chemicals, metallurgy, and non-metallic minerals. It’s especially good at making fine powders from white non-metallic ores, which are crucial for papermaking, coatings, plastics, rubber, and PVC.

Application Fields

The Clirik ultrafine vertical poller mill is adept at processing superfine dry powders of materials like calcite, limestone, marble, dolomite, barite, talc, kaolin, wollastonite, gypsum, feldspar, and pyrophyllite etc.

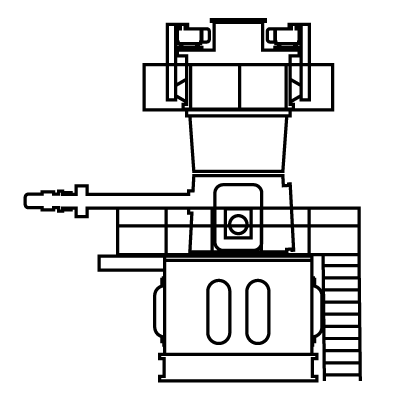

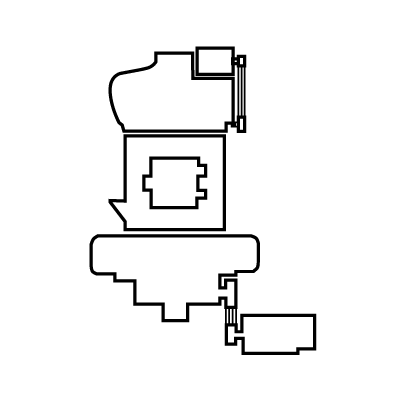

Main structures

The CLUM series ultrafine vertical roller mill is primarily composed of a motor, reduction gear, grinding rollers, grinding plate, pressure-applying device, classifier, mill body, oil station, and electrical system.

· Grinding rollers

The grinding plate’s passive rotation via friction is key for crushing and grinding materials.

· Pressure-applying device

It controls the gap between the grinding roller and plate to maintain roller pressure.

· Grinding plate

This section facilitates the grinding process and is driven by the reduction gear.

· Classifier

The multi-rotor classifier efficiently separates fine powders with centrifugal force.

Working principle

The Clirik CLUM Series Ultrafine Vertical Roller Mill operates through a streamlined process:

The main motor powers the grinding plate via a reduction gear.

High-pressure air enters through the air inlet, complementing the grinding action.

Materials are centrally fed into the grinding plate and spread outward by centrifugal force.

he grinding roller crushes and grinds the material into fine particles.

These particles are carried to the periphery by airflow and separated in the air ring.

Coarse particles are redirected for further grinding, while fine particles are extracted and collected as the final product.

Working Features

1. Separation of coarse granules and impurities

These are directed to the lower grinding chamber and discharged via a scraping plate.

2. High-precision multi-rotor classifier

Utilizing frequency control and adjustable rotor speed, it produces a wide range of particle sizes.

3. Adjustable hydraulic system pressure

This feature allows for precise adjustment of roller pressure, accommodating materials of varying hardness.

4. Electronic gap control device

Ensures a safe distance between the roller and grinding plate, effectively preventing excessive vibration due to uneven feeding.

Main Configuration

| Item | Model | CLUM 1425 | CLUM 1632 | CLUM 1736 |

| Plate Diameters (mm) | 1400 | 1600 | 1700 |

| Number Of Rollers (pieces) | 3 | 3 | 3 |

| Number Of Classifier (Kw) | 6 | 6 | 8 |

| Power Of Classifier (Kw) | 6 x 15 | 6 x 22 | 8 x 22 |

| Main Unit Power (Kw) | 250 | 315 | 380 |

| Blower Power (Kw) | 200 | 250 | 315 |

| Feed Size (mm) | <10mm | <10mm | <10mm |

| Moisture Of Feeding Material | <3% | <3% | <3% |

| Less than 2μm =34%output (t/h) | 9.5 – 11.5 | 12 – 14 | 14 – 16 |

| Less than 2μm= 50%output (t/h) | 4.5 – 5.5 | 5.6 – 7 | 6.7 – 8.4 |

| Less than 2μm = 70%output (t/h) | 1.5 – 2.5 | 1.9 -3.2 | 2.3 – 3.8 |

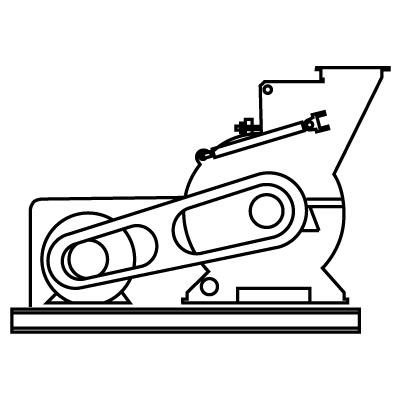

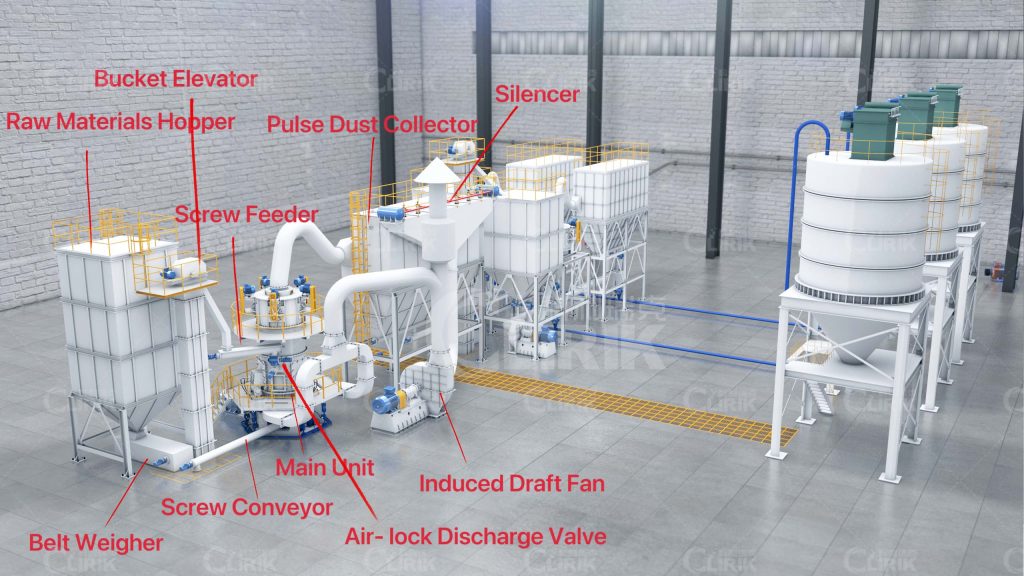

Powder Production Process Flow

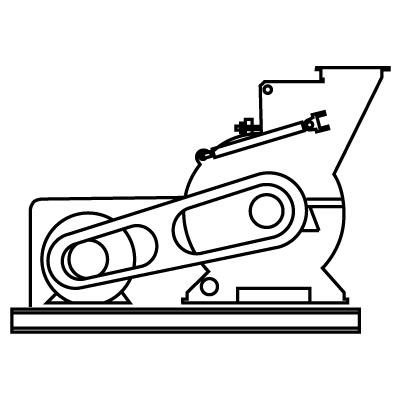

1. Feeding and Weighing

Raw materials are fed by a conveyor belt and precisely weighed, with iron contaminants removed by an iron remover.

2. Transport and Pulverization

The materials are then transported to the mill via an elevator and air lock, where they undergo pulverization.

3. Separation and Collection

The classifier separates the fine powder, directing it to a dust collector for collection.

4. Packaging and Sale

The collected powder is conveyed to the product hopper, ready for packaging and direct sale.

5. Recycling for Quality

Coarse materials are recycled back into the mill for re-grinding to ensure product fineness.

6. Safety Assurance

The conveyor’s iron remover is crucial for the safe and efficient operation of the ultrafine vertical roller mill.

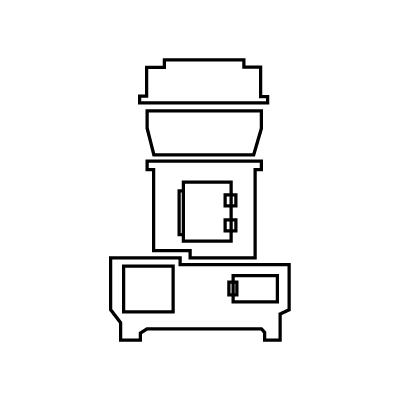

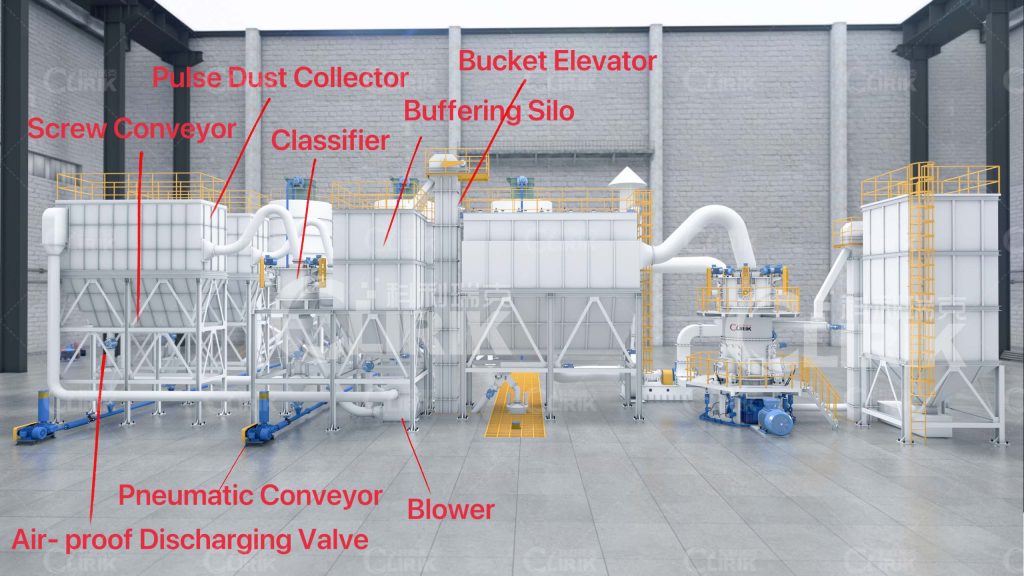

Secondary Classifying System

In some specific fields, high quality powders are demanded especially for powders cut-oft size, and 2um content percentage, thus secondary or third classifier system will be added to meet the demand.

With the ultra fine classifier as core equipment, the system includes buffering silo, bucket elevator, blower, air-proof discharging valve, classifier, pipes and ducts, bag filter, screw conveyor, pneumatic conveyor etc.

Other Main Products

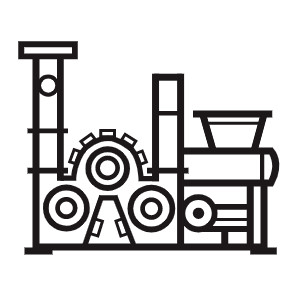

Clirik’s HGM Micro Powder Mill is known for stability and low maintenance, ideal for fine milling of over 100 brittle materials like calcite and limestone.

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: