Brief Introduction

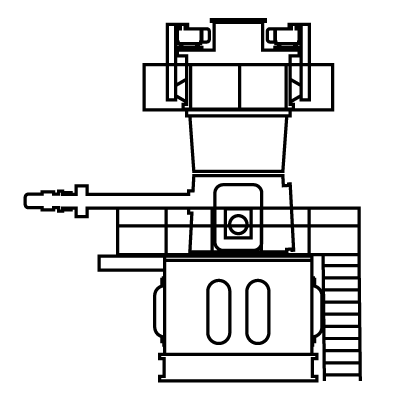

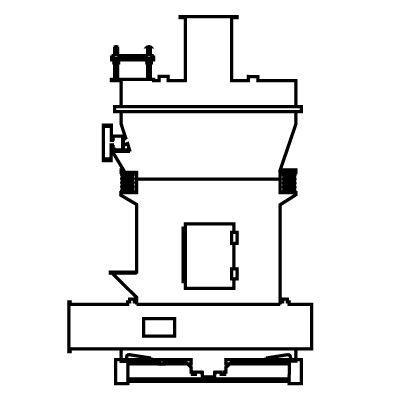

The Clirik Enhanced Roller Grinding Mill is designed for processing various non-flammable and non-explosive mineral materials with Moh’s hardness less than 6 and humidity less than 6%.

Application and Scope

It finds extensive applications in metallurgy, construction, chemical industry, mining, highway construction, and other fields.

The mill adjusts powder granularity from 50 to 325 meshes (315-45 microns) and handles over 400 materials like quartz , talc, ceramic and limestone and more.

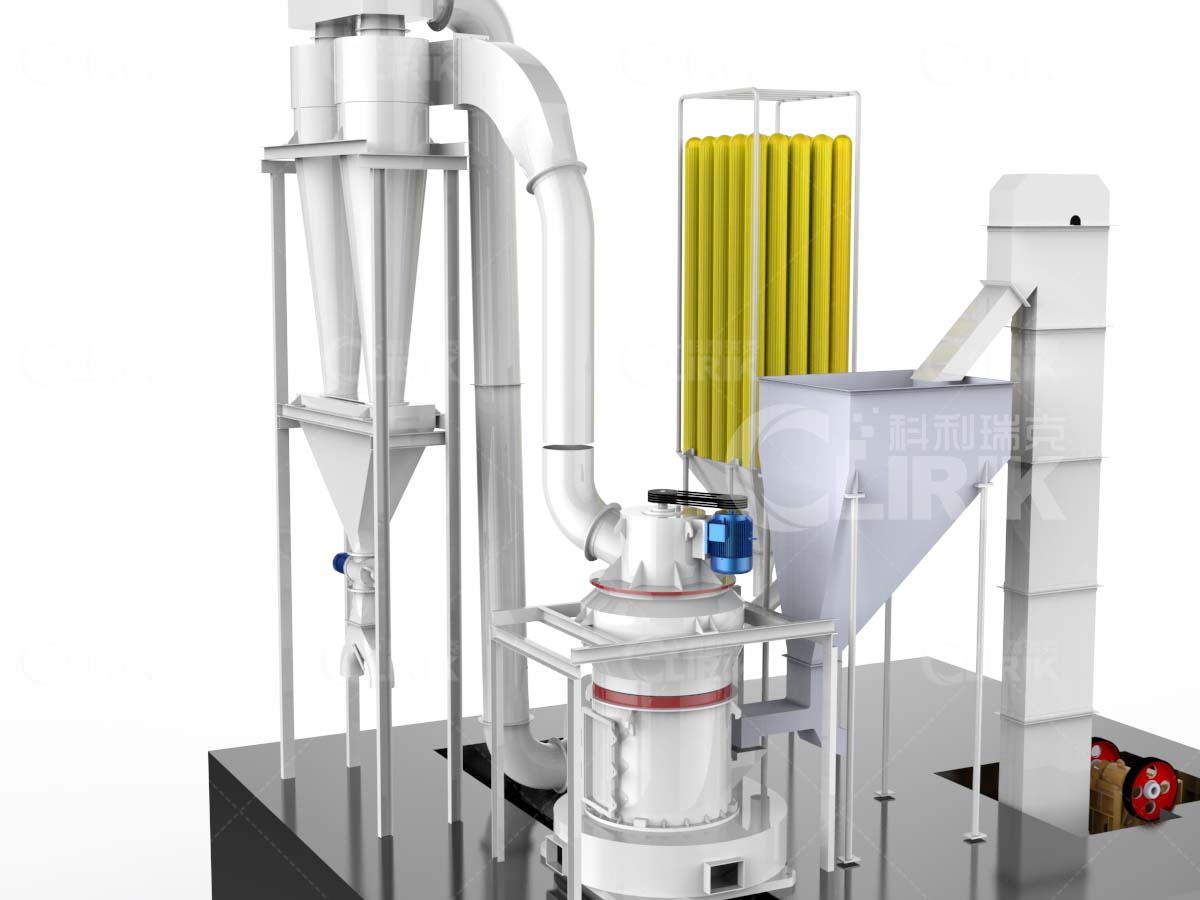

Working Principle

1. Initial Crushing

Large materials are initially processed in a jaw crusher to achieve the necessary particle size for further processing.

2. Feeding to the Main Unit

The crushed materials are then conveyed to a storage hopper and evenly fed into the main grinding unit by a vibrating feeder.

3. Powder Classification

The ground powder is carried by the airflow from the blower to a classifier, where it is sorted according to particle size.

4. Collection and Discharge

Particles that meet the fineness requirement are directed to a cyclone collector, separated, and collected as finished products, then discharged through a valve.

5. Airflow Recirculation

The purified airflow is returned to the blower via a pipe on top of the cyclone collector, creating a sealed circulation system that maintains air pressure balance.

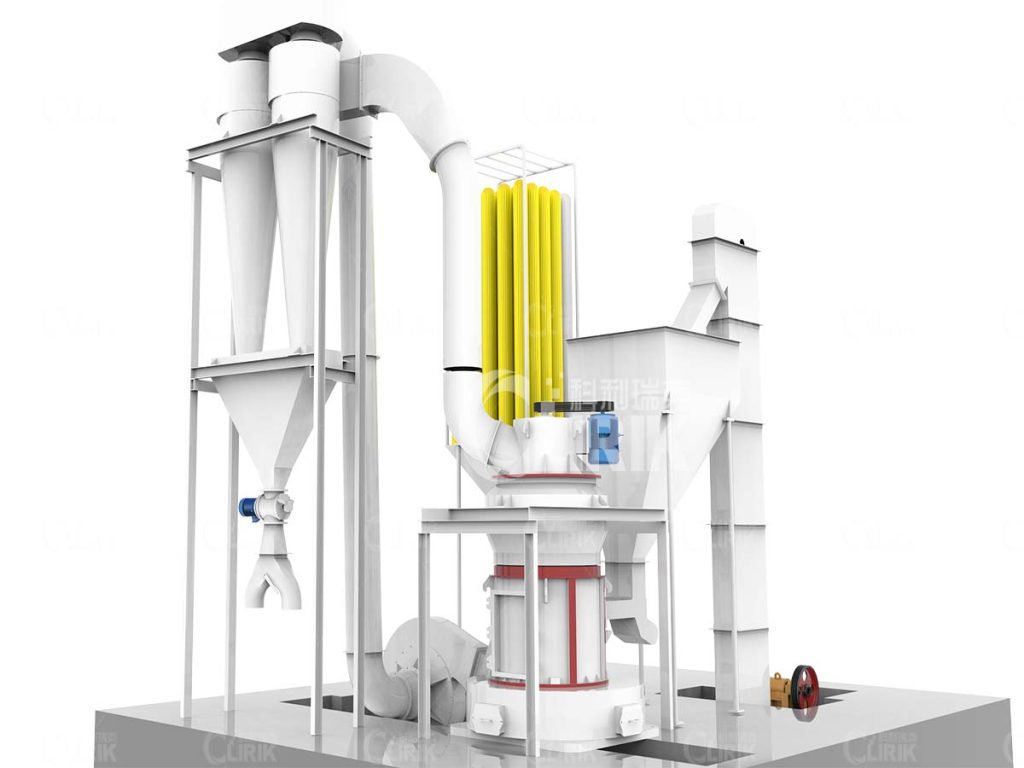

Working Features

Improved Grinding Efficiency

Enhanced grinding part increases efficiency with 10% higher grinding pressure and a 15-20% larger grinding area due to optimized roller layout.

Stable Operation with Triple Vibrating Damping

Minimizes noise and prevents machine vTriple damping minimizes vibration transmission in the main unit base, volute airflow housing, unit body, and grinding part for stable grinding conditions.

Adjustable Classifier Speed

New cage-type impeller with variable frequency drive (VFD) allows adjustable speed, expanding output size range to 80-425 mesh.

Extended Lubrication Cycle

Superimposed multistage seal on the grinding device prolongs the lubrication cycle for enhanced durability.

Main Specification

| Model | Roller Qty (pcs) | Roller Size (mm) | Ring External Dia (mm) | Ring H (mm) | Main Shaft Speed (r/min) | Feeding Size (mm) | mesh | Motor(kw) | Capacity (t/h) |

| CLRM9720 | 3–4 | 320*200 | 1077 | 200 | 145 | <20 | 80-500 | 45*15*37 | 1–7 |

| CLRM1280 | 3 | 370*240 | 1280 | 240 | 125 | <20 | 80-400 | 75*15*55 | 2–12 |

| CLRM1300 | 4 | 410*280 | 1390 | 280 | 112 | <20 | 80-400 | 110*22*90 | 3–15 |

| CLRM1620 | 4 | 450*300 | 1620 | 300 | 102 | <20 | 80-400 | 160*30*132 | 5–20 |

| CLRM1700A | 4 | 510*300 | 1700 | 300 | 102 | <30 | 80-325 | 185*37*160 | 6–25 |

| CLRM1720 | 4 | 510*300 | 1850 | 300 | 92 | <35 | 80-325 | 250*45*185 | 6–25 |

| CRLRM1900A | 4 | 600*300 | 1900 | 300 | 92 | <35 | 80-325 | 250*45*220 | 8–32 |

| CLRM2150 | 4 | 600*300 | 2150 | 300 | 85 | <35 | 80-325 | 315*45*280 | 12–35 |

Other Main Products

Clirik’s HGM Micro Powder Mill is known for stability and low maintenance, ideal for fine milling of over 100 brittle materials like calcite and limestone.

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: