Brief Introduction

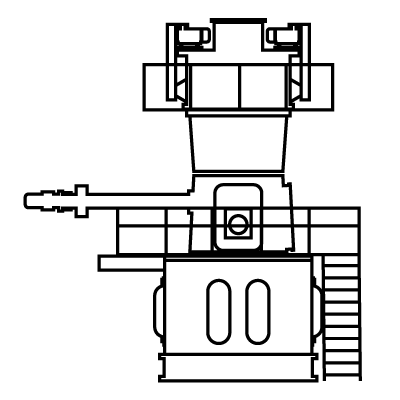

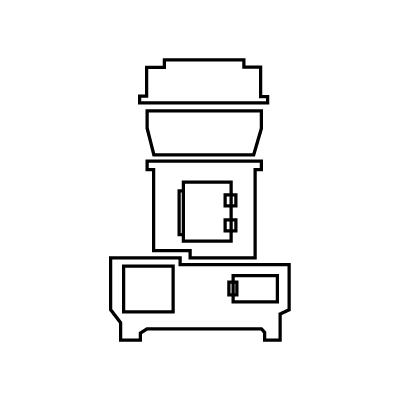

The Hammer Crusher is a device for crushing materials in the form of impact, which is divided into two parts: upper and lower parts, welded by steel plates after cutting.

Scope

The Hammer Crusher is adept at crushing medium-hard materials. Common applications include processing limestone, slag, coke, and coal within the cement, chemical, electric power, and metallurgy industries.

Application

The Hammer Crusher is extensively utilized across various industrial sectors due to its impact crushing capabilities. It is particularly effective in the mining, metallurgy, chemistry, cement, construction, refractory materials, and ceramics industries.

Working Features

Working Principle

Impact Crushing

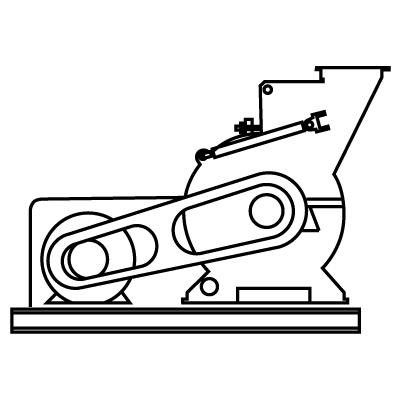

The hammer crusher primarily operates through the conversion of impact energy to crush materials. As materials enter the machine, they are struck by the high-speed rotating hammers.

Kinetic Energy Transfer

The crushed materials gain kinetic energy from the hammer heads, propelling them towards the baffle and screen bars within the frame.

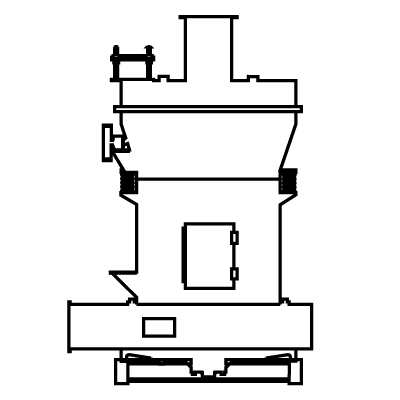

Material Separation

Inside the crushing chamber, materials are sorted by size. Those larger than the sieve holes are stopped by the screen bars, while smaller particles pass through.

Discharge Process

The final crushed materials are discharged through the gaps in the screen bars, marking the completion of the crushing operation.

Specification

| Model | PC400x300 | PC600x400 | PC800x600 | PC1000x800 |

| Rotor Diameter (mm) | 400 | 600 | 800 | 1000 |

| Rotor Width (mm) | 300 | 400 | 600 | 800 |

| r/min | 1100 | 1000 | 960 | 980 |

| Input Size (mm) | <100 | <220 | <350 | <400 |

| Output Size (mm) | 0-10 | 0-20 | 0-25 | 0-25 |

| Capacity (t/h) | 3-8 | 8-15 | 15-45 | 40-60 |

| Power (kw) | 11 | 18.5 | 45 | 75 |

| Hammer Number (pcs) | 16 | 20 | 28 | 30 |

| Weight (ton) | 0.5 | 1.6 | 4 | 6.5 |

| Dimension (mm) | 855*795*860 | 1150*1095*1230 | 2360*1490*1415 | 3072*1720*2121 |

Other Main Products

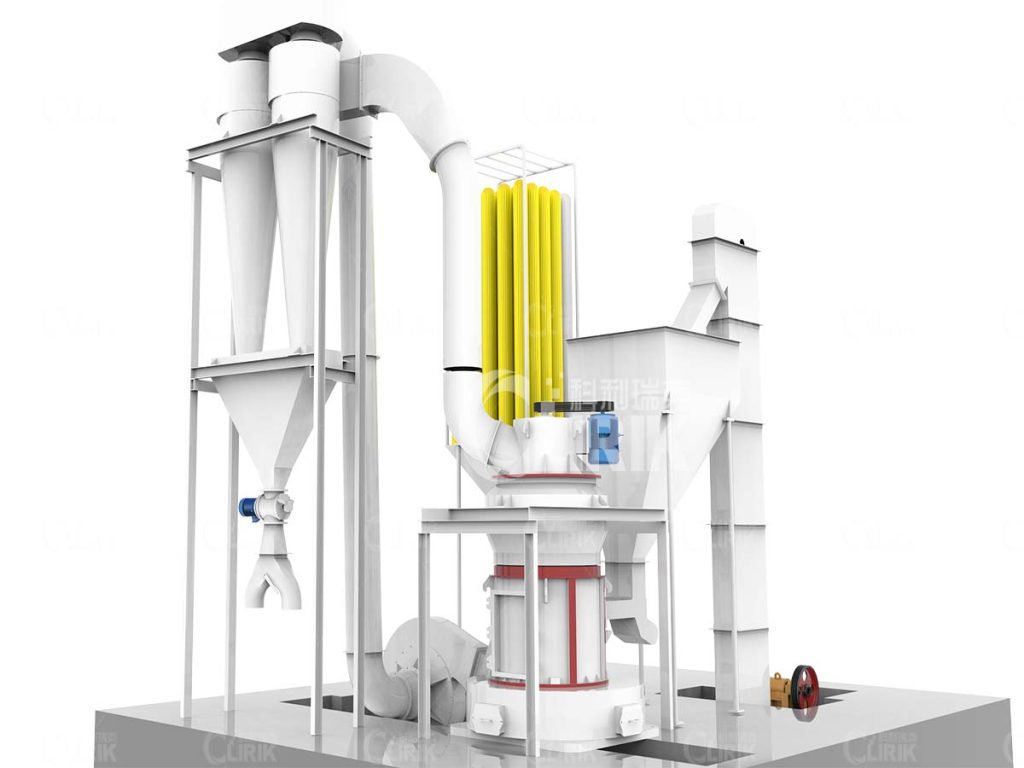

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: