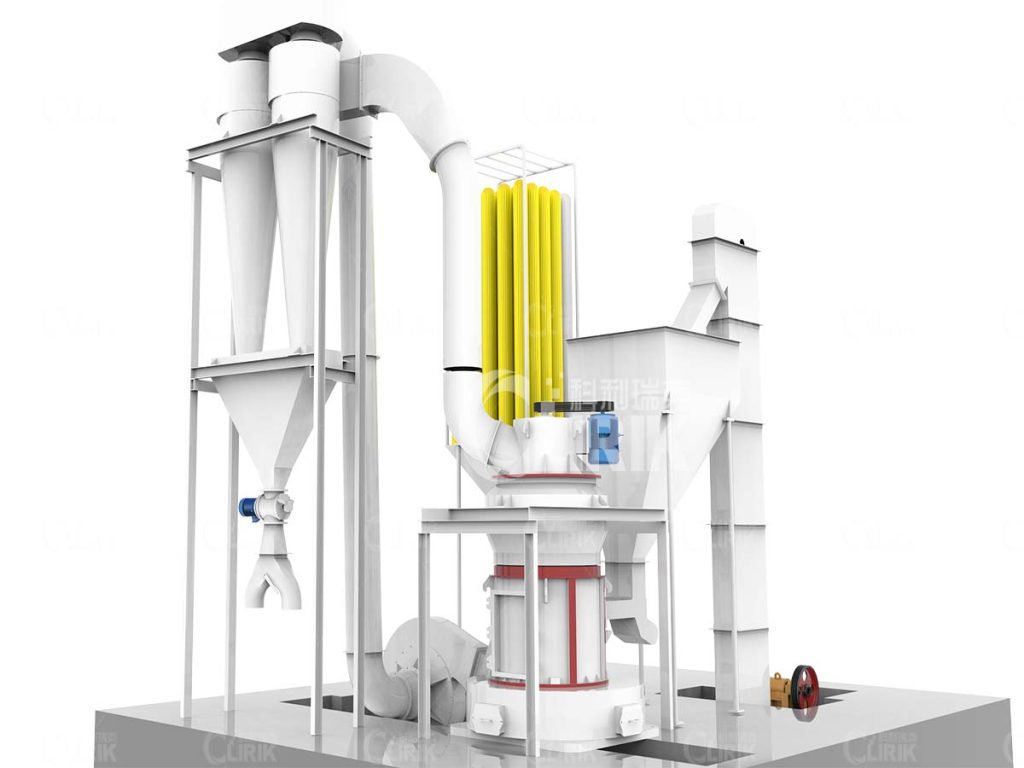

Brief Introduction

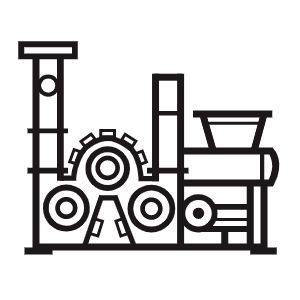

Our HGM Micro Powder Grinding Mill, endorsed by thousands of satisfied customers, stands out for its remarkable stability, ease of operation, and minimal maintenance requirements.

Scope

Engineered to achieve fine powder milling, it excels as the optimal equipment for processing non-inflammable, non-explosive, and brittle materials with a Moh’s hardness under six. This includes a wide spectrum of materials such as calcite, chalk, limestone, and dolomite, totaling over 100 types.

Application

Working Principle

1. Material Handling and Crushing Stage

· Larger materials are initially crushed by a hammer crusher and conveyed to a storage hopper.

· From there, they are evenly distributed to the upper distribution plate of the turn plate via a vibrating feeder and sloping feeding pipe.

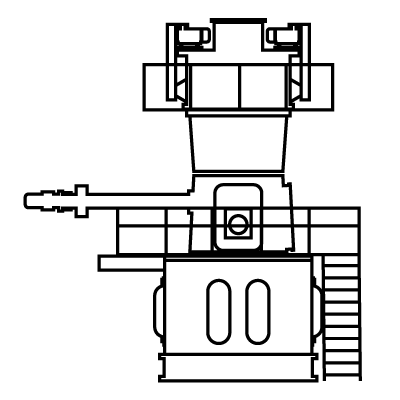

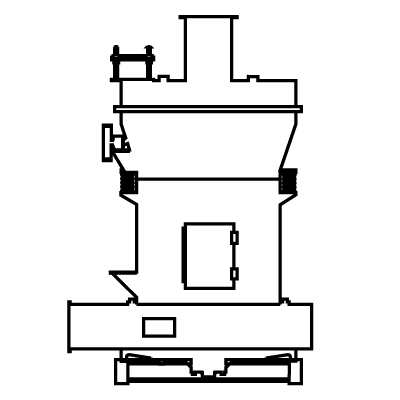

2. Grinding Process

· During operation, the main motor drives the main shaft and all grinding rollers through a reducer.

· The rollers roll around ring channels driven by the dial via plunger mechanisms.

· Under centrifugal force, materials move to the edge of the turn plate and enter the grinding chambers.

· There,they are repeatedly pressed,crushed,and ground into micro powder.

3. Airflow and Powder Handling Stage

· A high-pressure air blower continuously draws air into the mill.

· The airflow, carrying crushed materials, is directed to the classifier where a high-speed impeller screens and separates particles.

· Those not meeting size criteria return to the mill for further grinding, while appropriately sized particles, mixed with air, enter the cyclone powder collector.

· Most of the collected powders exit through the bottom discharge valve.

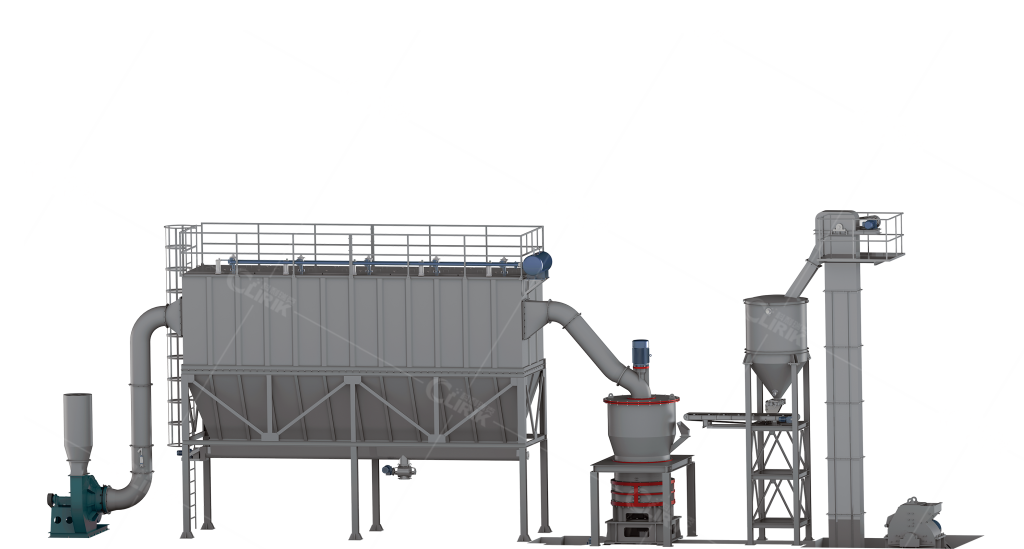

4. Dust Collection and Processing

· A portion of fine powders mixed with airflow proceeds to the dust cleaner.

· These adhere to the surface of filter bags; periodic release of high-pressure gas by the pulse valve causes vibrations in the filter bags, dislodging the fine powders which then fall down.

5. Finished Powder Packing and Clean Air Emission

· Both sets of materials are subsequently conveyed by the bottom conveyor for packing into finished powders.

· Clean, filtered air is emitted through the muffler’s air outlet.

Technical Advantages

1. Adjustable output size

It can produce particles ranging from 300 to 2500 mesh, providing flexibility for various applications.

2. Flexible capacity

With a capacity ranging from 0.5 to 30 tons per hour, HGM Micro Powder Grinding Mill meets diverse production needs efficiently.

3. High grinding efficiency

The classifier achieves a fineness of 5 microns in a single pass, ensuring superb grinding performance.

4. Intelligent control and automatic feedback

This enables rapid and stable adjustment of powder size, enhancing operational efficiency.

5. Efficient turbine classifier

Delivers precise particle size control, ensuring consistent and accurate results.

Main Specification

| Model | HGM80 | HGM90L | HGM100L-Ⅱ HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number(layer) | 3 | 3-4 | 4 | 4 | 4 |

| Roller Number(piece) | 18-21 | 24-29 | 28-36 | 30-40 | 30-44 |

| Main Shaft Speed(r.p.m) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size(mm) | ≦20 | ≦20 | ≦20 | ≦20 | ≦20 |

| Finished Size(μm/mesh) | 74-5(200-2500) | 74-5(200-2500) | 74-5(200-2500) | 100-6(150-2000) | 100-9(150-1500) |

| Capacity(t/h) | 0.5-5.5 | 0.8-6.5 | 1.2-10 1.2-11 | 2.5-20 | 5-45 |

| Overall Dimension(L*W*H,m) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 |

Power Parameter

| Unit:KW | HGM80 | HGM90L | HGM100L-Ⅱ HGM100P | HGM125L | HGM1680L |

| Main Unit | 75 | 2*45 | 132-150 | 185-200 | 315 |

| Classifier | 18.5 | 18.5-30 | 30-37 | 75 | 132 |

| Blower | 45 | 55 | 75 | 110 | 200-220 |

| Crusher | 18.5 | 18.5 | 18.5 | 45 | 45 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 7.5 |

| Feeder | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Discharging Valve | 2*0.75 | 1.1 | 1.1 | 1.5 | 2*1.5 |

| Air Compressor | 11 | 15 | 22 | 37 | 55 |

Specialized Parts

Multi- head Classifier

Clirik Multi-head Classifier works seamlessly with different types of grinding mills to efficiently separate materials such as calcite, gypsum, barite, kaolin, talc, limestone, silica, Mg/AL(OH)3, carbon black, metal powder, and wood powder.

Other Main Products

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: