Brief Introduction

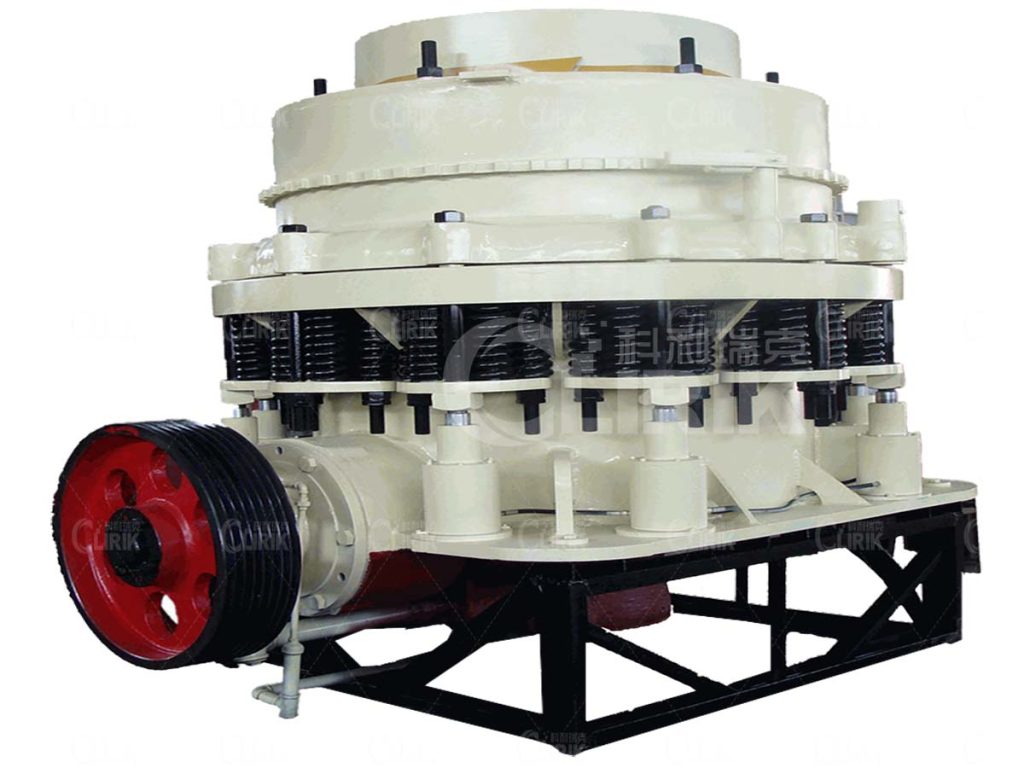

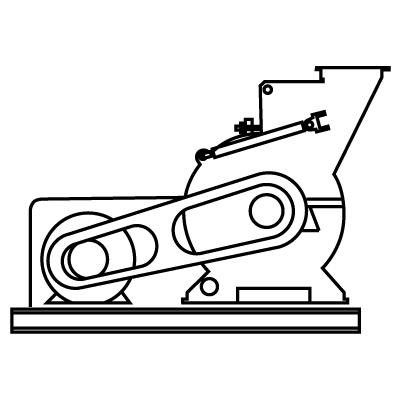

The Clirik Hydraulic Cone Crusher is an advanced model that integrates German technology, enhancing capacity and efficiency for a wide range of applications, from medium to super fine crushing.

Scope and Application

It not only improves the production capacity and crushing efficiency, but also expands the application range, from limestone to basalt, with excellent crushing performance for medium-size crushing, fine crushing, and super fine crushing operations.

This crusher represents an enhanced version over traditional spring cone crushers, suitable for mining and construction industries, making it the optimal choice for large stone crushing plants.

Working Features

Enhanced crushing ratio and production efficiency.

Reduced consumption of spare parts and lower operational costs.

Hydraulic protection and hydraulic cavity clearing ensure high automation.

Minimal interruptions to production and reduced maintenance downtime.

Diverse crushing cavities cater to various requirements.

Working Principle

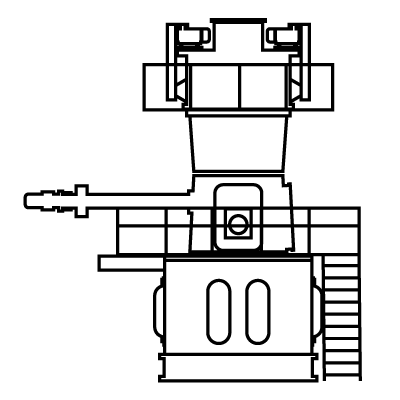

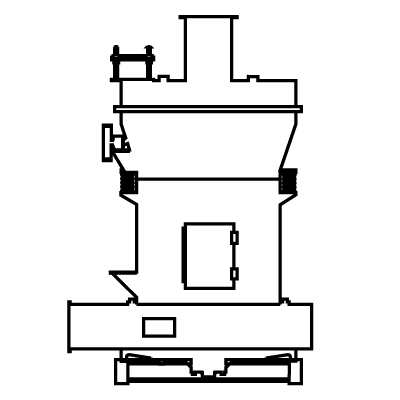

Clirik HPY Series high-efficiency hydraulic cone crusher operates with the eccentric sleeve playing a crucial role.

1. Cone Movement and Crushing Action

The movable cone’s rotary and pendulum movements actuate the crushing walls, which apply pressure and torque to the raw material against the rolling ace tabular wall.

2. Laminated Crushing Principle

Employing the principles of laminated crushing, the materials are subjected to crushing and polishing forces that vary according to their grain structure, coming from multiple directions.

3. Cone Movement and Crushing Action

The movable cone’s rotary and pendulum movements actuate the crushing walls, which apply pressure and torque to the raw material against the rolling ace tabular wall.

4. Laminated Crushing Principle

Employing the principles of laminated crushing, the materials are subjected to crushing and polishing forces that vary according to their grain structure, coming from multiple directions.

5. Aggregate Formation and Sizing

The crushing process effectively forms stable aggregates. Materials that meet the size criteria pass through the gap in the crushing wall, whereas larger particles are retained for additional crushing until they conform to the desired specifications.

Specification

| Model | Chamber | Closing output (mm) | Input Size (mm) | Capacity(t/h) | Cone Diameter (mm) | Power (kw) | Weight (ton) |

| HPY-160 | C | 13 | 150 | 120-240 | 950 | 160 | 13 |

| F | 6 | 76 | 55-180 | ||||

| HPY-220 | C | 13 | 225 | 150-430 | 1160 | 220 | 19 |

| F | 6 | 86 | 90-260 | ||||

| HPY-315 | C | 13 | 290 | 190-610 | 1400 | 315 | 26 |

| F | 6 | 100 | 108-320 | ||||

| HPY-400 | C | 13 | 320 | 230-700 | 1500 | 400 | 33 |

| F | 6 | 110 | 145-430 |

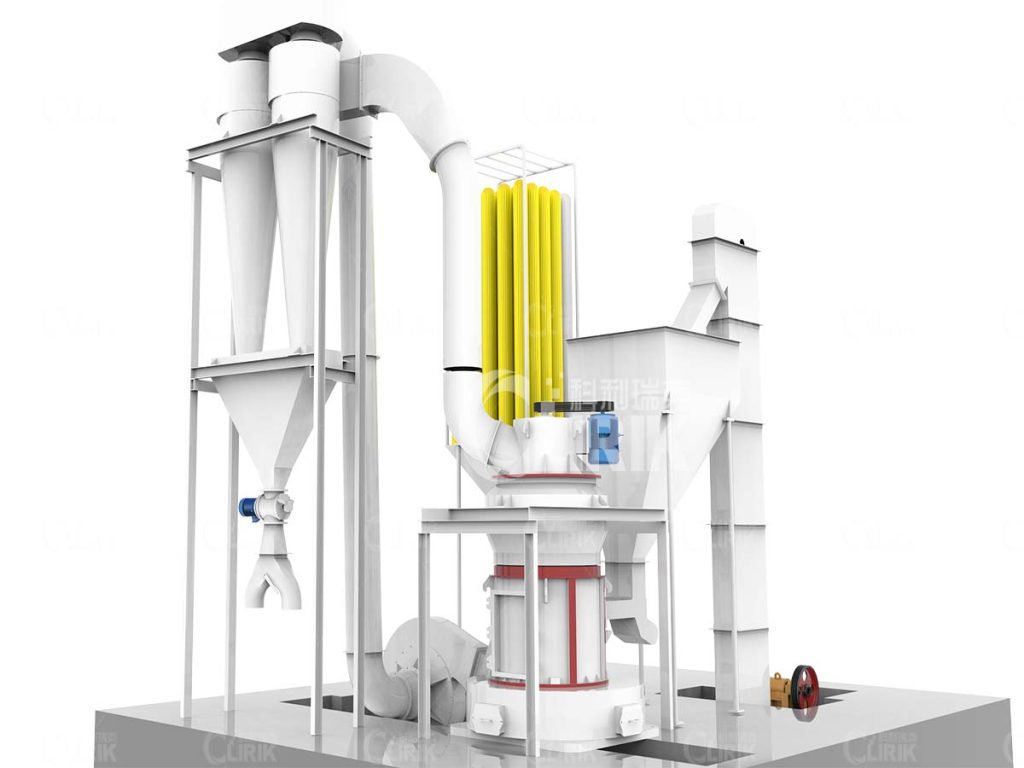

Other Main Products

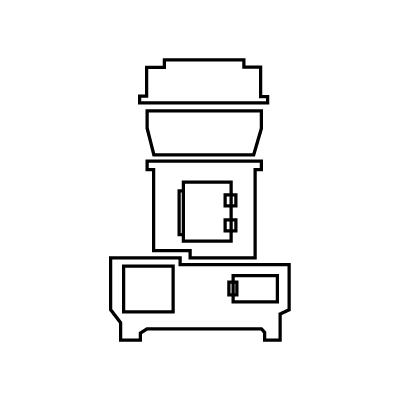

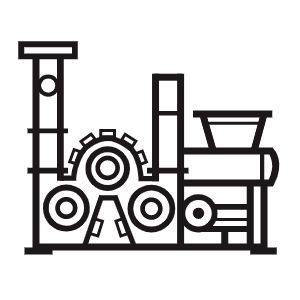

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: