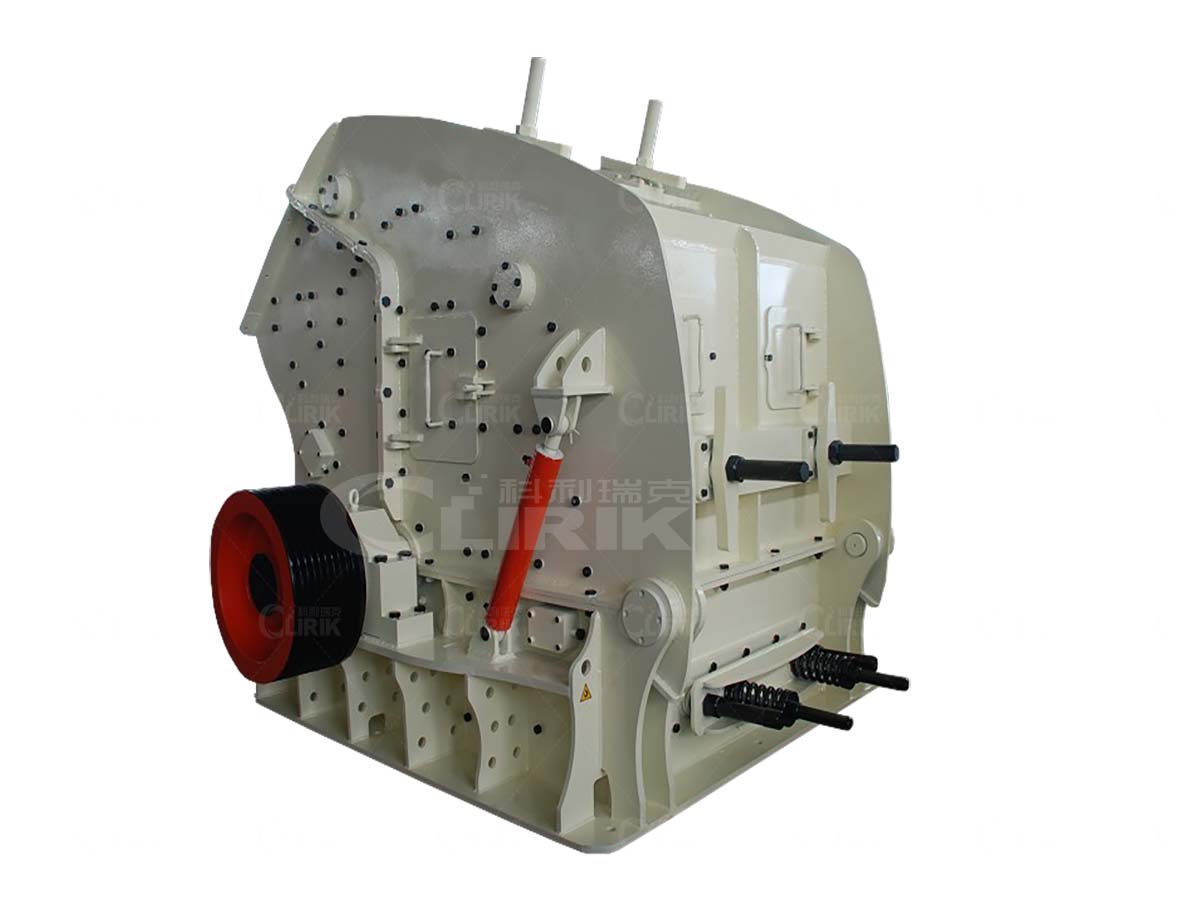

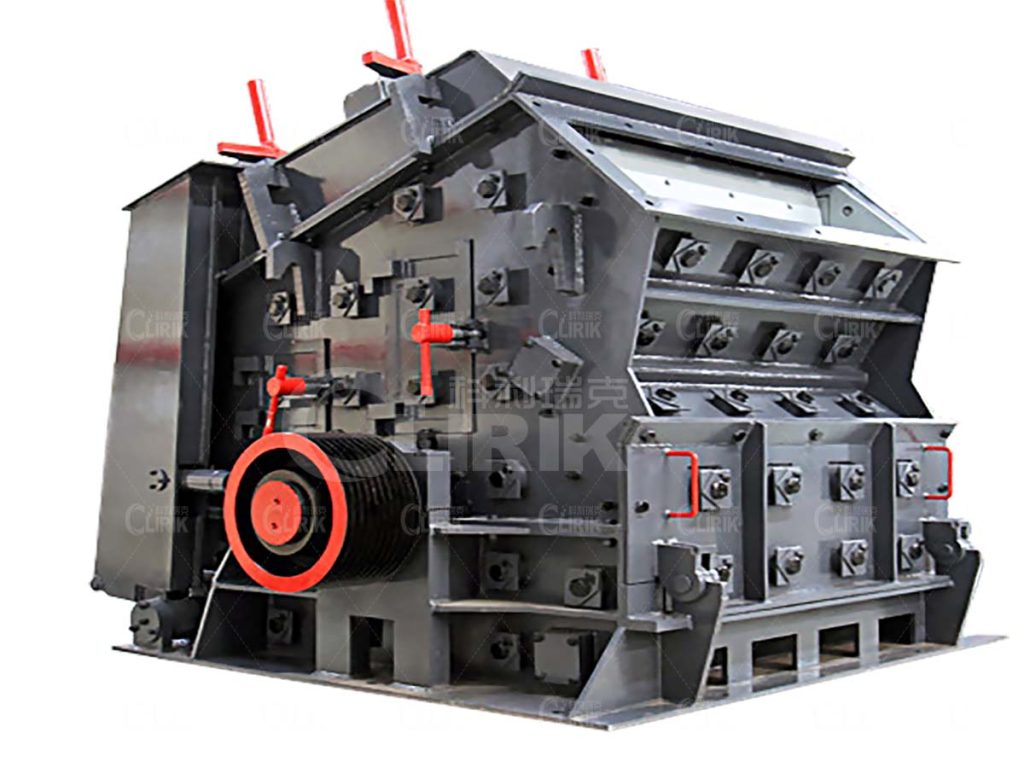

Brief Introduction

The Clirik Impact Crusher is capable of crushing various materials with a maximum feed size less than 500mm and compressive strength less than 360 MPa.

Its final product is of good cubic shape, without tension and cracks.

Application

This equipment finds wide application in mining, transportation, energy, construction, and chemical industries.

Working Features

Hammer made of high-chrome and liner board made of wear-resistant material.

Specially designed tooth impact plate for crushing hard rock efficiently with high efficiency and low consumption.

Produces cubic final product; adjustable discharge opening simplifies crushing flow chart.

Simple adjustment of impact rack and rotor clearance to vary the size and shape of the end product.

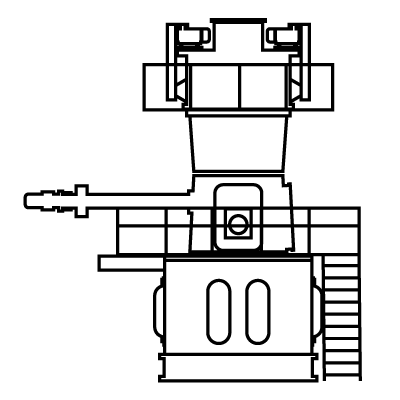

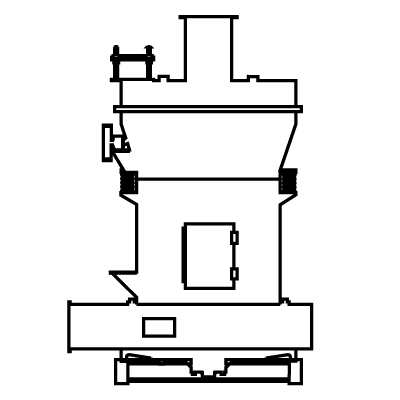

Working Principle

The Impact Crusher operates by striking materials with rotor-driven impact energy.

When the crusher is operational, the motor drives the rotor to rotate at high speed, where the blow bars installed on the rotor strike the materials entering the crushing chamber.

The impacted materials are thrown to the impact devices around the rotor, where they are crushed until they achieve the required size.

The adjustable clearance between the impact rack and the rotor can be modified to control the size and shape of the final product.

Specification

| Model | Size (mm) | Feeder Size (mm) | Input Size (mm) | Capacity (t/h) | Motor (kw) | Weight (ton) |

| PF-0608 | φ644×740 | 320×770 | ≤100 | 10-20 | 30 | 4 |

| PF-0807 | φ850×700 | 400×730 | ≤300 | 15-30 | 30-45 | 8.13 |

| PF-1007 | φ1000×700 | 400×730 | ≤300 | 15-60 | 27-55 | 9.5 |

| PF-1010 | φ1000×1050 | 400×1080 | ≤350 | 50-90 | 55-75 | 14 |

| PF-1013 | φ1000×1300 | 650×1350 | ≤350 | 80-120 | 90-110 | 12 |

| PF-1210 | φ1250×1050 | 400×1080 | ≤350 | 70-130 | 110-132 | 17 |

| PF-1214 | φ1250×1400 | 400×1430 | ≤350 | 90-180 | 132-160 | 22 |

| PF-1315 | φ1320×1500 | 860×1520 | ≤400 | 120-250 | 180-260 | 26 |

| PF-1320 | φ1320×2000 | 860×2030 | ≤500 | 160-350 | 300-375 | 30 |

Other Main Products

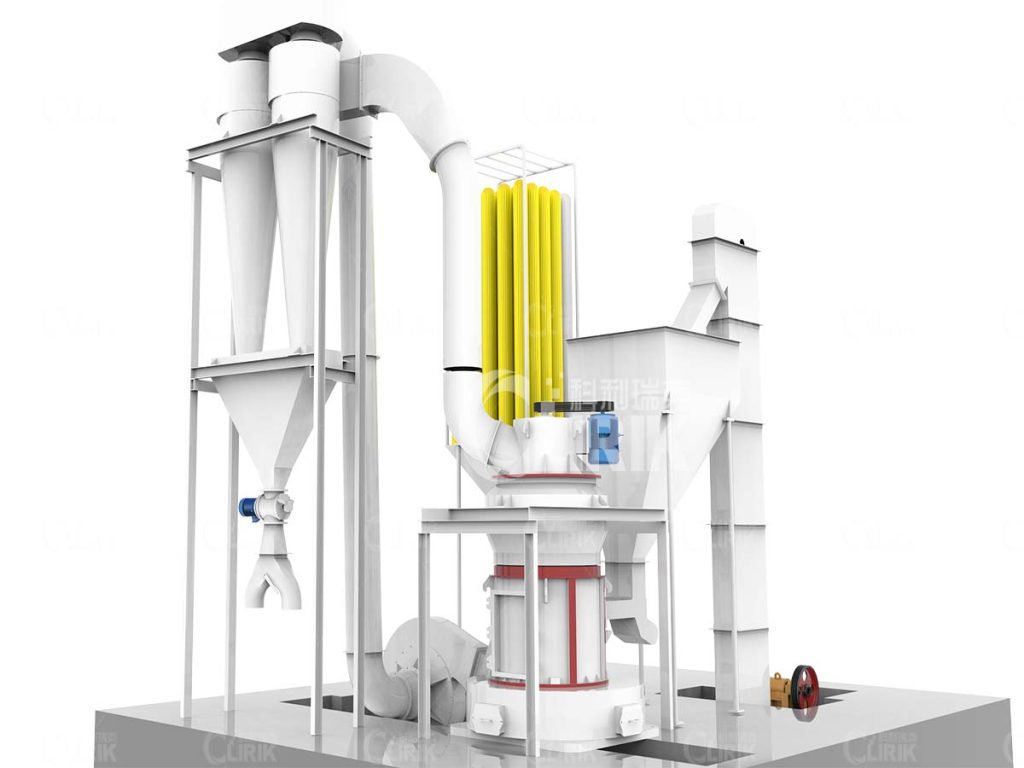

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: