Brief Introduction

Clirik CLG series powder surface coating machine is essential for enhancing non-metallic materials such as plastic, rubber, adhesives, and high polymer composites with mineral powders.

Application

It excels in surface modification for heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesium hydroxide, barium sulfate, illite claystone, pyrophyllite, hexagonite, and more.

Structure and Function

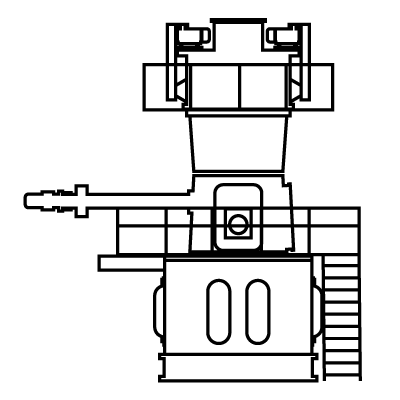

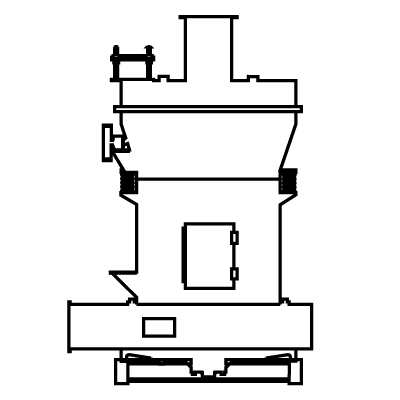

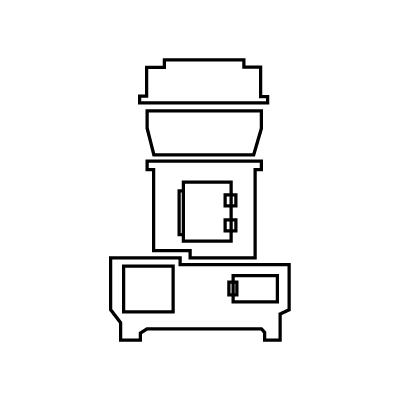

Hopper

Materials are fed into the hopper from silos or bags. Feeding materials should have a humidity of less than 0.5%.

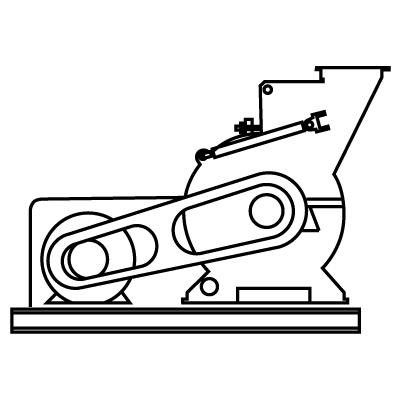

Conveying device

Equipped with double screws and adjustable speed for stable material flow.

Agent adding system with temperature control

Features an automatic temperature control system allowing flexible melting temperature settings, suitable for various solid and liquid modifying agents.

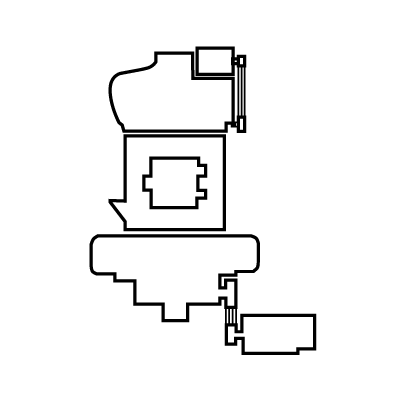

Main machine

This enables rapid and stable adjustment of powder size, enhancing operational efficiency.

Cyclone dust collector

Utilizes diffusion technology.

Impulse type bag dust collector

Incorporates a new-generation pleated filter, offering large filtration capacity in a compact space.

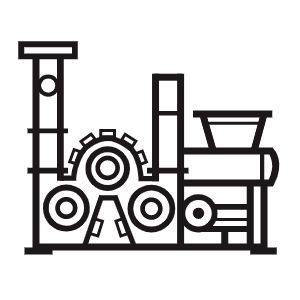

Working Principle

The powder surface treatment is primarily achieved using three modifying rollers.

Dry powder and the specified agent are introduced into the rollers simultaneously.

Through high-speed rotation, they form a fluidizing vortex.

The modification process occurs as a result of intense heat generated by rapid shearing, collision, and friction between the rotor, stator, and powder particles.

Main Specification

| Model | Main Power (kw) | Blower Power (kw) | Speed of shaft (r.p.m) | Capacity (kg/h) | Weight (t) | Overall Dimension (L*W*H)mm |

| CLG-200D | 3*4 | 2.2 | 5700 | 40-150 | 1 | 3200*600*2200 |

| CLG-3/300 | 3*18.5 | 5.5 | 4500 | 500-1800 | 3 | 5800*1800*5600 |

| CLG-3/600 | 3*37 | 15-22 | 2700 | 2000-4000 | 10 | 11200*3100*6200 |

| CLG-3/900 | 3*75 | 45 | 2000 | 4000-7000 | 20 | 21000*3800*6500 |

Other Main Products

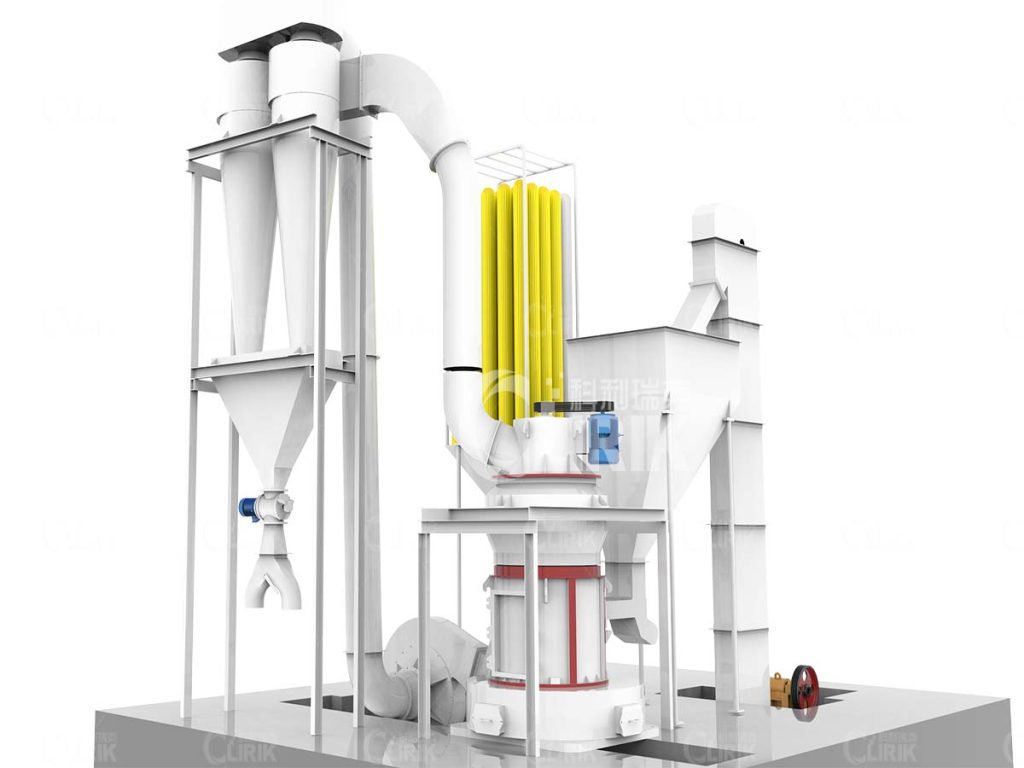

Clirik’s HGM Micro Powder Mill is known for stability and low maintenance, ideal for fine milling of over 100 brittle materials like calcite and limestone.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: