Brief Description

Clirik DMC Pulse Bag Filter, innovatively designed by integrating the best features of similar products, utilizes advanced pulse cleaning technology to efficiently remove dust with minimal resistance.

Features and Advantages

1. High Efficiency

Our pulse bag filter effectively purifies dusty gases with particles larger than 0.1 micrometers.

2. Exceptional Collection Efficiency

Achieves a general collection efficiency of over 99.5%, ensuring stable and reliable performance with easy operation.

3. Versatile Adaptability

Capable of capturing dust particles of various properties, with its collection efficiency unaffected by dust characteristics or resistance properties.

Working Principle

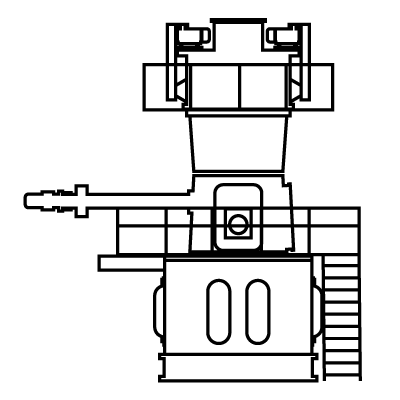

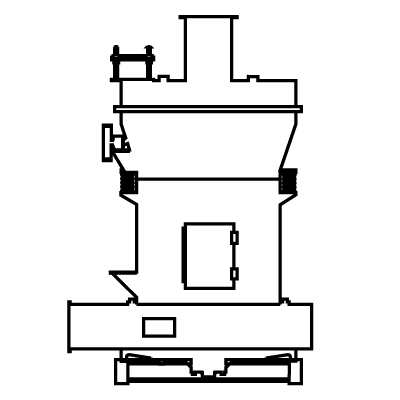

The Clirik pulse bag filter is composed of key sections including an upper box, middle box, and a lower box which acts as a hopper.

1. Dust Intake and Coarse Particle Separation

When dusty gas enters the upper box, the flow area suddenly expands, causing coarse particles to be separated and fall into the hopper due to the distribution of airflow and inertial forces.

2. Fine Dust Collection

Fine, low-density dust particles then proceed into the dust chamber where they adhere to the surface of the filter bags.

3. Pulse Cleaning Mechanism

A programmable logic controller (PLC) system initiates the operation of pulse valves, injecting compressed air into the filter bags. This causes the bags to expand and vibrate, effectively dislodging the fine powders that have accumulated on their surfaces.

4. Particle Discharge

The dislodged particles fall into the hopper and are subsequently discharged through the discharge valve.

5. Clean Air Exhaust

Finally, the purified air is expelled through the exhaust pipe, completing the dust removal process.

Specification

| Model | DMC64 | DMC72 | DMC84 | DMC96 | DMC108 | DMC120 | DMC160 |

| Filter Area (m2) | 30 | 34 | 40 | 45 | 51 | 57 | 75 |

| Filter Bag Quantity (PCS) | 64 | 72 | 84 | 96 | 108 | 120 | 160 |

| Filter Bag Size (mm) | φ150 x 2000 | φ150 x 2000 | φ150 x 2000 | φ150 x 2000 | φ150 x 2000 | φ150 x 2000 | φ150 x 2000 |

| Air Volume (m3/h) | 5400-10800 | 6480-12960 | 7560-12960 | 8640-17280 | 9270-19440 | 10800-21600 | 11000-21600 |

| Temperature (Celsius) | <120℃ | <120℃ | <120℃ | <120℃ | <120℃ | <120℃ | <120℃ |

| Device Resistance (Pa) | 1200Pa-1500Pa | 1200Pa-1500Pa | 1200Pa-1500Pa | 1200Pa-1500Pa | 1200Pa-1500Pa | 1200Pa-1500Pa | 1200Pa-1500Pa |

| Dust Collector Efficiency (%) | 99%-99.5% | 99%-99.5% | 99%-99.5% | 99%-99.5% | 99%-99.5% | 99%-99.5% | 99%-99.5% |

| Pulse Pressure (m/min) | 2-4m/min | 2-4m/min | 2-4m/min | 2-4m/min | 2-4m/min | 2-4m/min | 2-4m/min |

| Air Compressed Volume (Mpa) | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 |

| Filter Wind Velocity (m3/min) | 0.2-0.8 | 0.25-1 | 0.3-1.2 | 0.3-1.3 | 0.4-1.5 | 0.4-1.7 | 0.165-1.7 |

| Electromagnet Pulse Valve Quantity (PCS) | 10 | 12 | 14 | 16 | 18 | 20 | 20 |

| Measurement (mm) | 1700*1700*4750 | 1900*1700*4750 | 2400*1550*4750 | 2400*1700*4750 | 2400*1850*4750 | 2400*2000*4750 | 3230*2100*4750 |

| Discharge Valve Motor (Power) | 0.75KW | 0.75KW | 0.75KW | 0.75KW | 0.75KW | 0.75KW | 0.75KW |

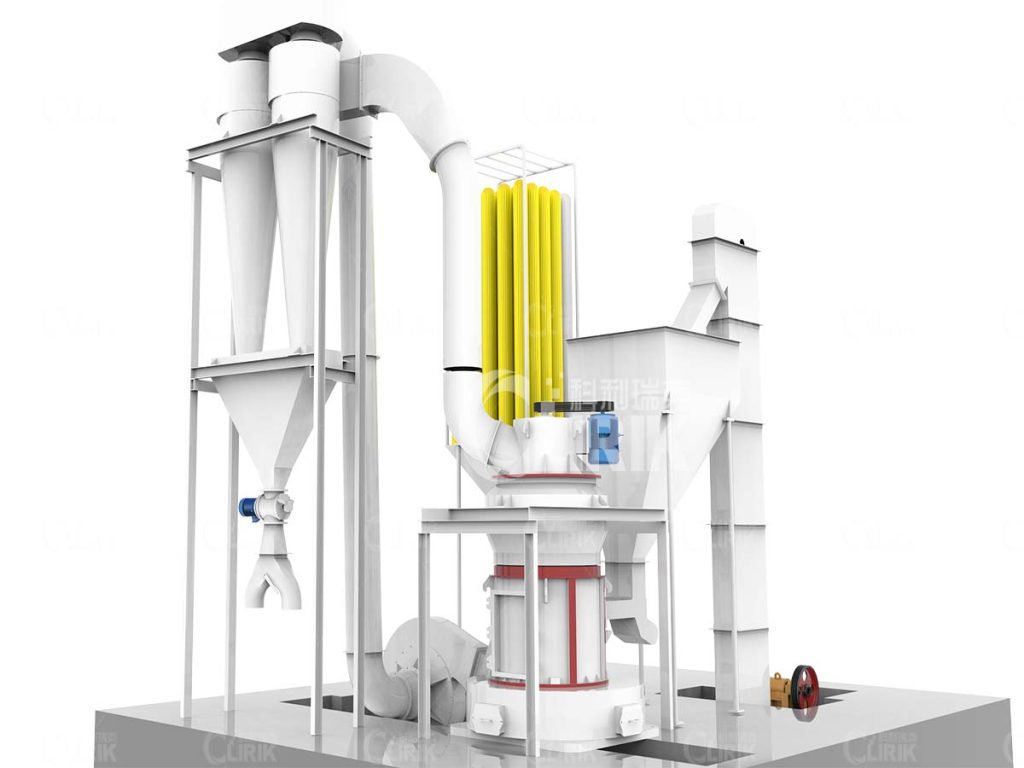

Other Main Products

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

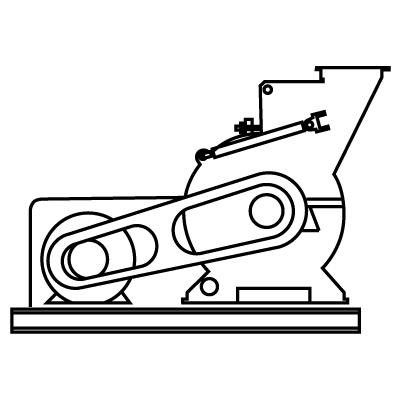

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.