Brief Introduction

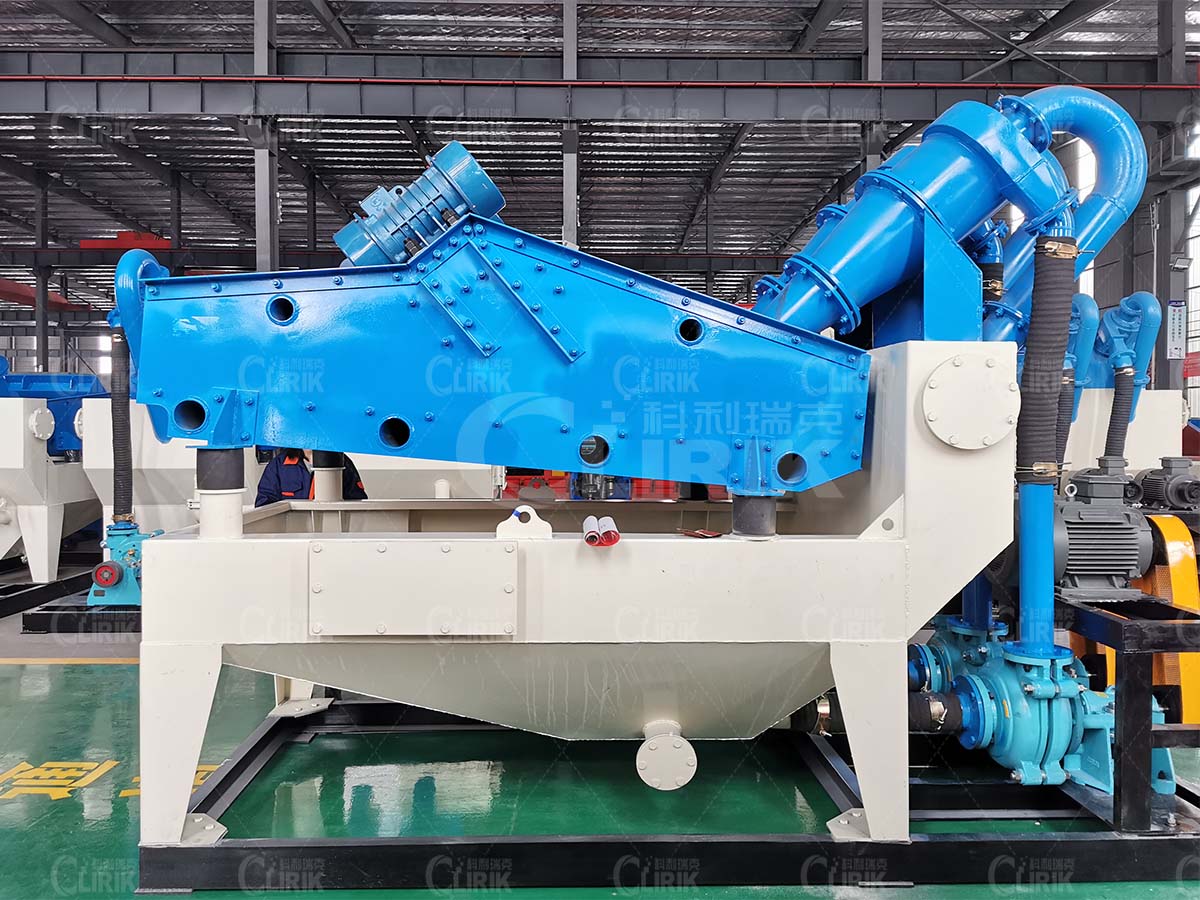

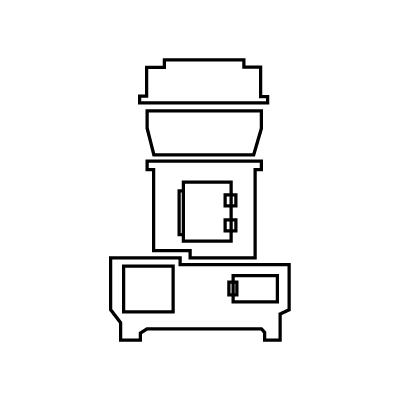

The Sand Collecting System incorporates advanced global technologies tailored to various sand types, effectively minimizing fine sand loss.

Application

The Sand Collecting System widely applied in raw glass material processing systems and manufactured sand production lines, our CJ series addresses challenges in fine sand recovery.

Working Features

· Addresses challenges of high fineness sand loss and low powder content.

· Enhanced equipment lifespan with polyurethane cyclones for efficient slurry concentration and liquid clarification.

· Recovers up to 85% of fine grain materials from effluent, offering unparalleled technological and economic advantages.

· Efficient fine sand recovery reduces sedimentation tank workload and cleaning costs.

· Reduces natural stock time of fine sand, enabling immediate sale.

Working Principle

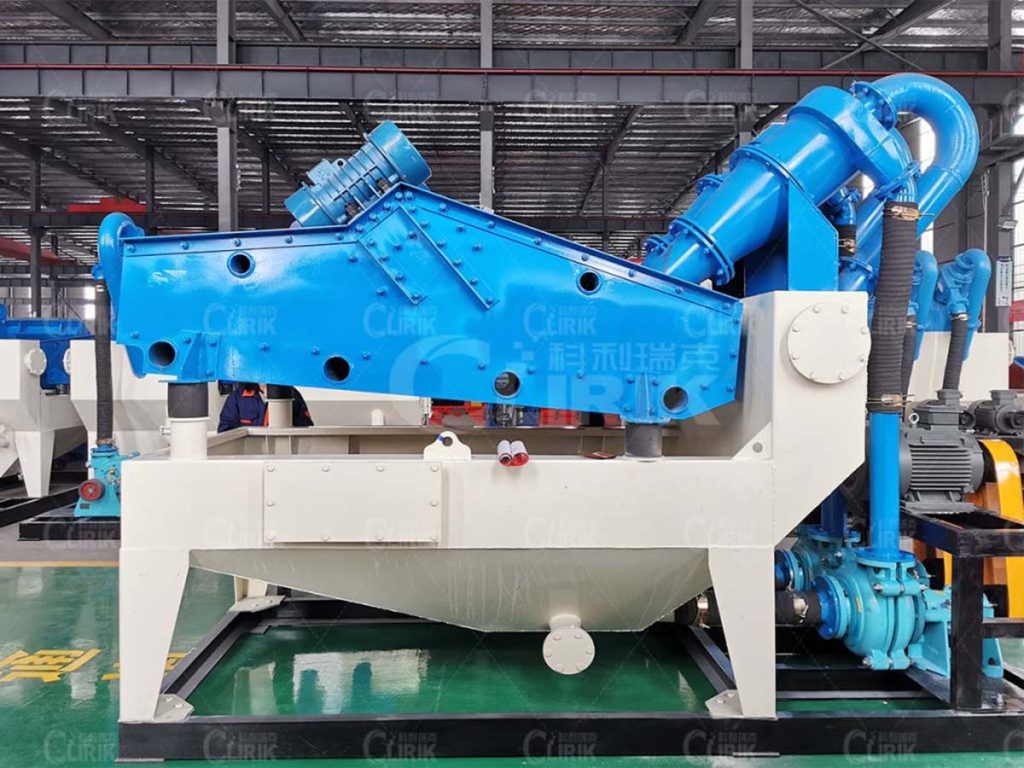

1. Centrifugal Classification

The sand-water mixture is introduced into the cyclone for centrifugal classification, separating materials based on their densities.

2. Dewatering and Separation

The heavier grit is directed to a vibrating screen where sand is effectively separated from water during the dehydration process.

3. Recycling of Fines

Fine sand and mud are recycled back to the pool via a recycling box, ensuring continuous circulation within the system.

4. Liquid Discharge

Excess liquid is discharged from the system when the pool level rises, maintaining optimal operation conditions.

5. Material Recovery and Adjustment

The vibrating screen efficiently recovers 70% to 80% of material weight, with its performance finely tuned by controlling pump speed, pulp density, water flow, and aperture settings.

Specification

| Model | Pump Powder | Pump Material | Specifications | Sieve Dehydration Material | Sieve Dehydration Powder (kw) | Capacity (m3/h) | Weight (kg) |

| LZ250 | 7.5-11 | Cr26 | 250 | PU | 2*0.55 | 30-80 | 2050 |

| LZ300 | 11-15 | Cr26 | 300 | PU | 2*0.75 | 40-100 | 2200 |

| LZ350 | 15 | Cr26 | 350 | PU | 2*0.75 | 70-130 | 2555 |

| LZ550 | 15-22 | Cr26 | 550 | PU | 2*1.1 | 100-220 | 3250 |

| LZ650 | 18.5-30 | Cr26 | 650 | PU | 2*1.1 | 120-272 | 3945 |

| LZ750 | 37-55 | Cr26 | 750 | PU | 2*1.5 | 180-350 | 4900 |

| LZ900 | 55-65 | Cr26 | 900 | PU | 2*2.2 | 250-500 | 5650 |

Other Main Products

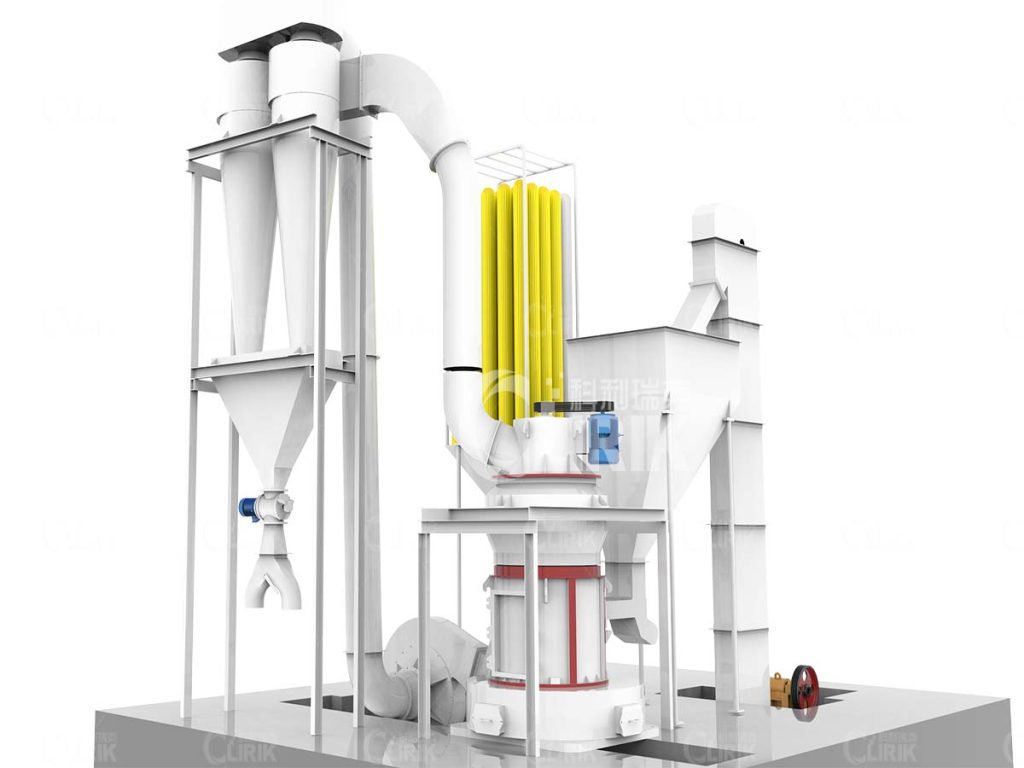

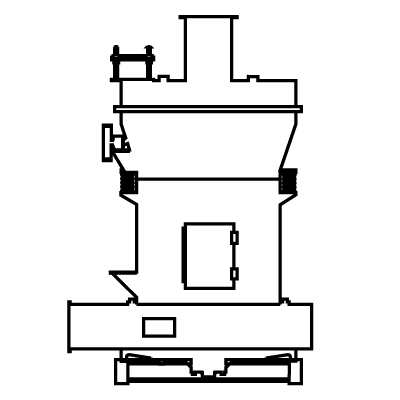

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

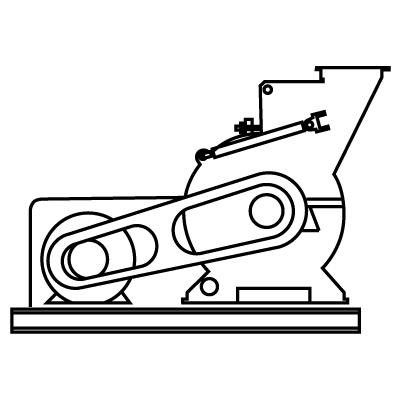

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

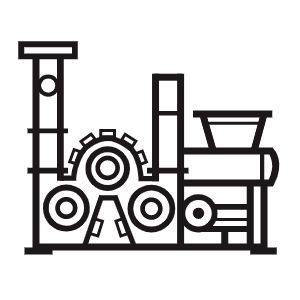

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: