Brief Introduction

The LS screw conveyor represents a refined iteration of the GX model, known for its reliability, durability, adaptability, and ease of installation.

Scope and Application

It efficiently transports powder, granular, and block materials (up to 200°C) such as coal powder, coal ash, clay, sand, cement, and urea.

Beyond applications in concrete and asphalt batching, it serves various industries including chemical processing, construction, food production, and metallurgy.

Features

1. Enhanced Bearing Protection

The LS screw conveyor improves upon the GX type by relocating bearings outside the frame, thereby eliminating risks to bearing longevity caused by loose seals and material leakage.

2. Compact and User-Friendly Design

It features a straightforward design, compact footprint, low noise, effective sealing, and user-friendly operation and maintenance.

3. Versatile Application and Configuration

With its broad applicability, convenient inlet and outlet configurations facilitate multi-point material feeding and discharge.

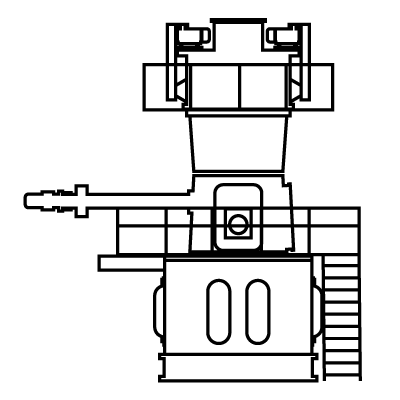

Working principle

The screw conveyor has a spiral blade on a shaft inside a chute, with bearings at both ends and a drive unit at one end, featuring top and bottom openings.

Here’s how it operates:

1. Inlet Entry

Material is introduced into the conveyor system through the designated inlet.

2. Initial Engagement

The spiral blade’s reverse thrust engages the material, causing it to rotate with the shaft due to radial forces and friction.

3. Axial Movement

Despite the rotation induced by the blade, gravity and chute friction prevent the material from fully rotating with the blade, leading to axial movement along the chute.

4. Spiral Advancement

The material progresses in a spiral path, advancing forward while also tumbling in a circumferential motion.

Specification

| Type | LS159 | LS219 | LS250 | LS315 |

| Diameter (mm) | 159 | 219 | 250 | 315 |

| Screw Pitch (mm) | 100 | 175 | 200 | 250 |

| Ratate speed (r/min) | 83 | 83 | 90 | 71 | 70 |

| Conveying Capacity (m3/h) | 2-6 | 5-12 | 22 | 18 | 36 |

Other Main Products

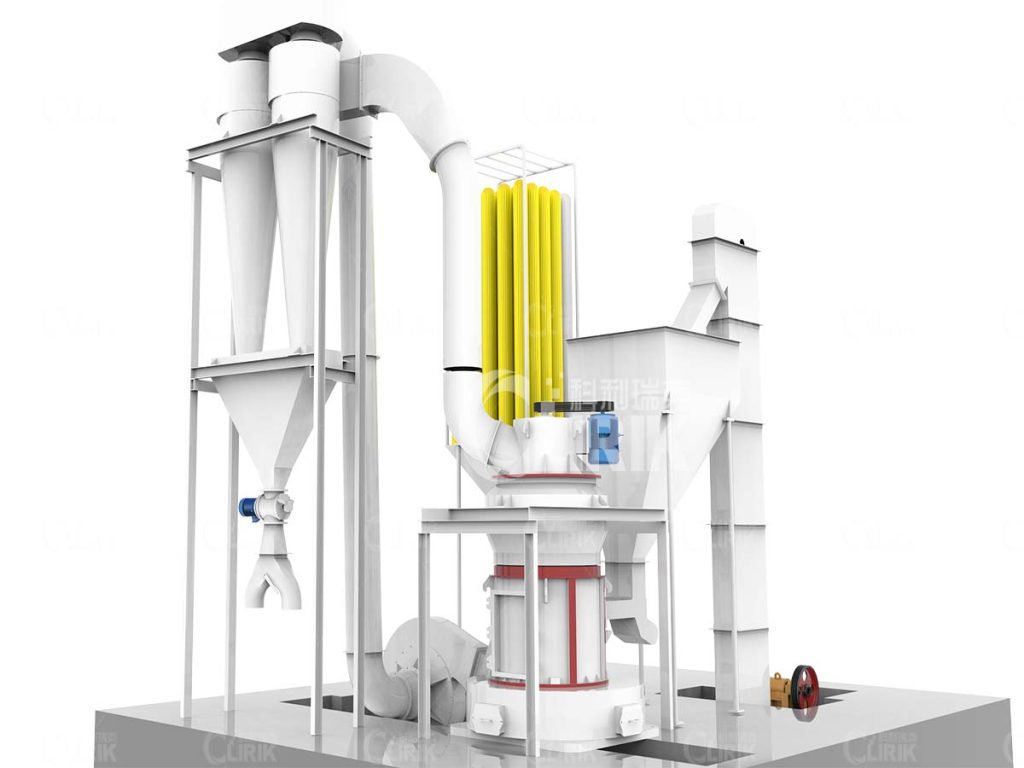

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: