Brief Introduction

The Screw Sand Washing Machine is designed for sand processing, electric pole factory, construction site, and concrete dam, various sands classifying, and dewatering purposes.

Working Principle

· It features an inclined structure, with a 15° inclination angle.

· Within the water tub, three weir plates create a sedimentation pool.

· The screw head is immersed within this pool and is driven by an electric motor via a reducer, ensuring continuous rotation.

· Fresh water is fed into the sediment pool through a porous plate at the bottom.

· This machine effectively performs the functions of washing, dewatering, and classifying.

Specification

| Model | XSD2610 | XSD3016 | XSD3620 |

| Wheel Diameter and Width (mm) | φ2600*1000 | φ3000*1600 | φ3600*2000 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 |

| Capacity (t/h) | 20-50 | 50-120 | 120-180 |

| Power (Kw) | 7.5 | 15 | 18.5 |

| Weight (ton) | 2.68 | 3.26 | 4.3 |

| Dimension (mm) | 3320*2125*2670 | 3820*2686*3085 | 4500*3206*3480 |

Other Main Products

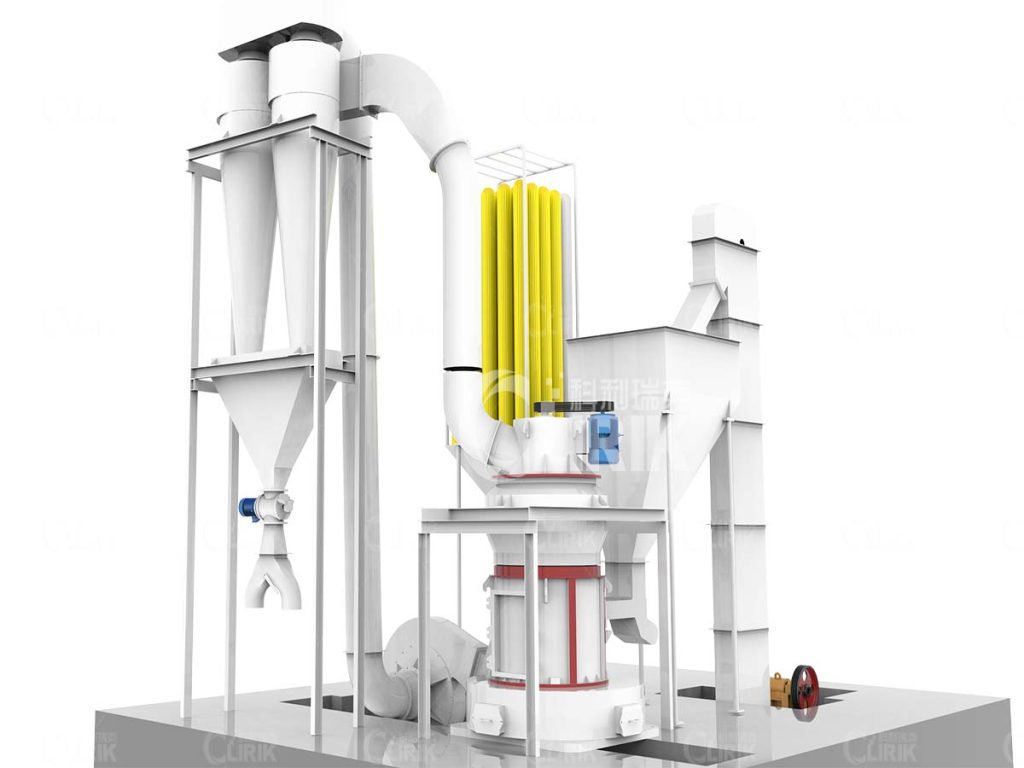

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: