Brief Introduction

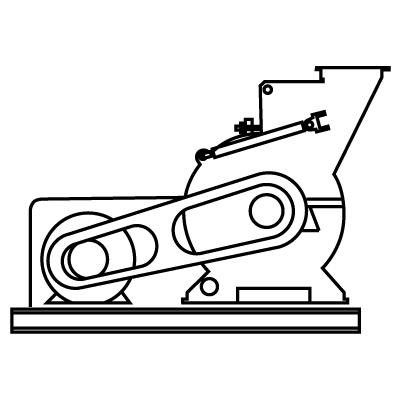

Spring cone crushers are engineered for long-term reliability, with a simple design for ease of use. Crafted from high-quality American steel for durability, they are globally recognized for their robustness and low maintenance.

Working Features

· Stable performance and high reliability.

· Easy maintenance and operation.

· Laminated crushing for better particle shape.

· Cost-effective with wide application versatility.

· Various types of crushing chambers available.

Working Principle

The motor drives the eccentric bushing to rotate through the V-belts, pulley, shaft, pinion, and gear.

The mantle rotates with the eccentric bushing, causing the mantle to approach and move away from the concave liner, crushing the stone into smaller pieces which fall through the bottom discharge opening.

Specification

| Model | Cone Diameter (mm) | Chamber | Feeder Size Close Side (mm) | Feeder Size Open Side (mm) | Output Size (mm) | Capacity (ton/hour) | Rotor Speed (r.p.m) | Power(kw) | Weight(ton) | Dimension(mm) |

| CS75B | 900(3′) | M | 83 | 102 | 9-22 | 45-91 | 580 | 75 | 15 | 2821*1880*2164 |

| L | 159 | 175 | 13-38 | 59-163 | ||||||

| CS75D | 914(3‘) | S | 13 | 41 | 3-13 | 27-90 | 580 | 75 | 15 | 2821*1880*2410 |

| M | 33 | 60 | 3-16 | 27-100 | ||||||

| L | 51 | 76 | 6-19 | 65-140 | ||||||

| CS60B | S | 109 | 137 | 13-31 | 109-181 | 485 | 185 | 27 | 2800*2342*2668 | |

| M | 188 | 210 | 16-31 | 132-253 | ||||||

| L | 216 | 241 | 19-51 | 172-349 | ||||||

| CS240B | S | 188 | 209 | 16-38 | 181-327 | 485 | 240 | 55 | 3911*2870*3771 | |

| M | 213 | 241 | 22-51 | 258-417 | ||||||

| L | 241 | 268 | 25-64 | 299-635 | ||||||

| CS400B | S | 253 | 278 | 19-38 | 381-726 | 435 | 315 | 110 | 4613*3251*4732 | |

| M | 303 | 334 | 25-51 | 608-998 | ||||||

| L | 334 | 369 | 31-64 | 870-1400 |

Other Main Products

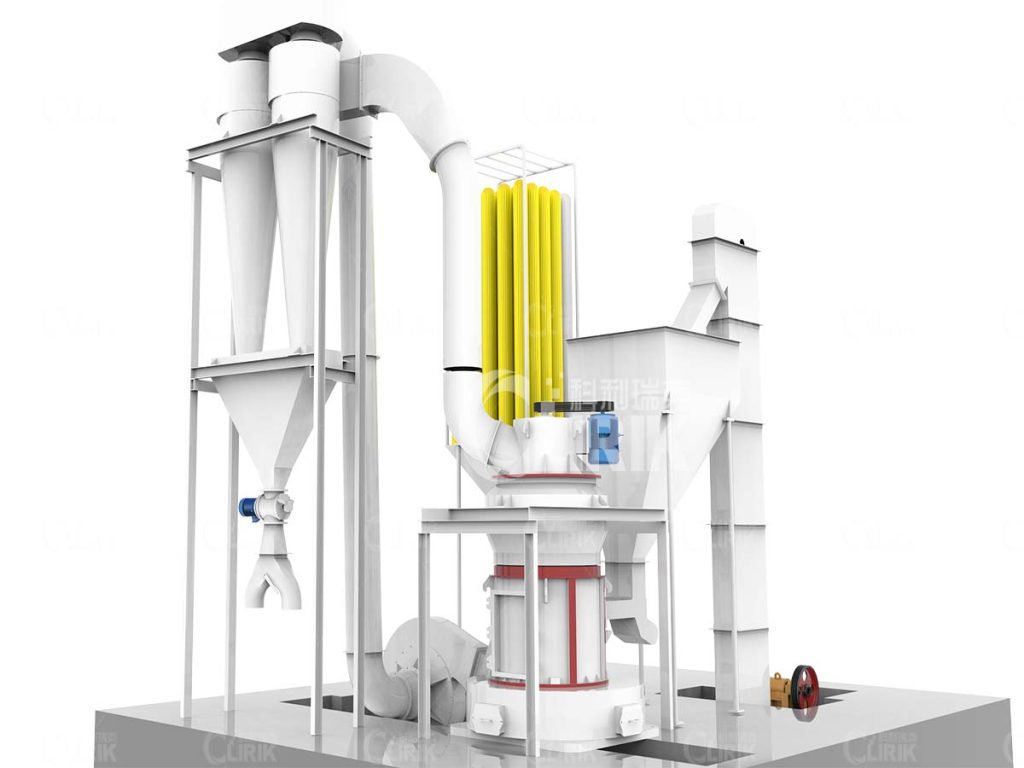

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

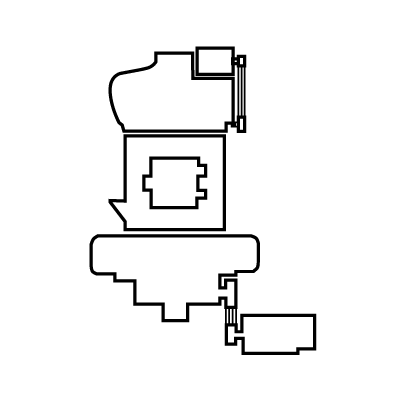

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: