Brief Introduction

The Vibrating Screen is designed for multi-layered efficiency. It utilizes an eccentric shaft vibration exciter and partial block to adjust the amplitude, ensuring clear screening of various specifications.

Application

With its streamlined design and numerous configuration options, this screen is highly suitable for industries such as quarrying, building materials, transportation, energy, and chemistry. It is recognized for its reliable maintenance and safe operation.

Working Features

· Multilayer and high efficient

· Simple structure and easy maintenance

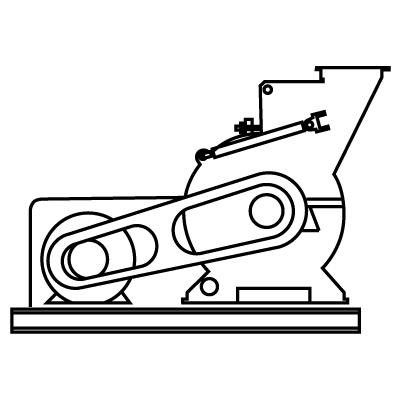

· Tire Coupling for Flexible and Stable Operation

· Large handling capacity and long life span

· Low consumption and little noise

Working Principle

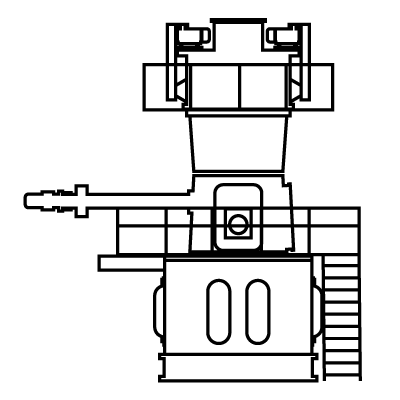

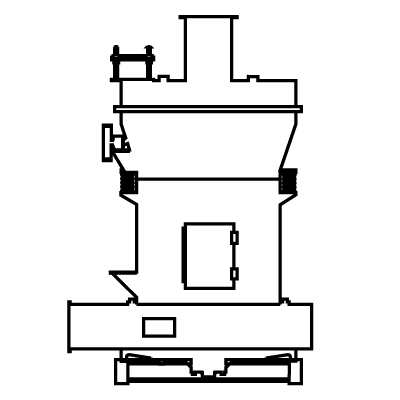

The Clirik Circular Vibrating Screen functions as a single mass forced vibrating system. It is composed of a screen box, an exciter, and other movable components that act as the mass, with a metal coil spring acting as the elastic element.

1. Excitation and Force Generation

The motor drives the exciter via tire-type couplings, creating strong centrifugal forces from the high-speed rotation of the eccentric block.

2. Continuous Circular Motion

The generated force induces the screen box to perform continuous, mandatory circular motions.

3. Material Separation Process

The inclined screen’s force propels materials in a continuous motion, separating them on the upward throw and allowing passage on the downward fall, completing the classification cycle.

Specification

| Model | ScreenSpec (mm) | Screen Deck | Screen Mesh (mm) | Feeder Opening (mm) | Capacity (t/h) | Power (kw) | Vibrating Frequency (r/min) | Double Amplitude (mm) |

| 2Yk1237 | 1200×3700 | 2 | 4~50 | ≤200 | 10~80 | 15 | 960 | 4~8 |

| 3YK1237 | 1200×3700 | 3 | 4~50 | ≤200 | 10~80 | 15 | 960 | 4~8 |

| 2YK1548 | 4800×1500 | 2 | 3~100 | ≤400 | 30~275 | 15 | 870 | 5~9 |

| 3Yk1548 | 4800×1500 | 3 | 3~100 | ≤400 | 30~275 | 15 | 870 | 5~9 |

| 2YK1848 | 4800×1800 | 2 | 3~100 | ≤400 | 56~330 | 18.5 | 870 | 5~9 |

| 3YK1848 | 4800×1800 | 3 | 3~100 | ≤400 | 56~330 | 18.5 | 870 | 5~9 |

| 2YK1860 | 6000×1800 | 2 | 3~100 | ≤400 | 65~586 | 22 | 870 | 5~9 |

| 3YK1860 | 6000×1800 | 3 | 3~100 | ≤400 | 65~586 | 22~30 | 870 | 5~9 |

| 2YK2160 | 6000×2100 | 2 | 3~100 | ≤400 | 81~720 | 30 | 730 | 5~9 |

| 3YK2160 | 6000×2100 | 3 | 3~100 | ≤400 | 81~720 | 30~37 | 730 | 5~9 |

| 2YK2460 | 6000×2400 | 2 | 3~150 | ≤400 | 100~810 | 37 | 770 | 5~9 |

| 3YK2460 | 6000×2400 | 3 | 3~150 | ≤400 | 100~810 | 37 | 770 | 5~9 |

Other Main Products

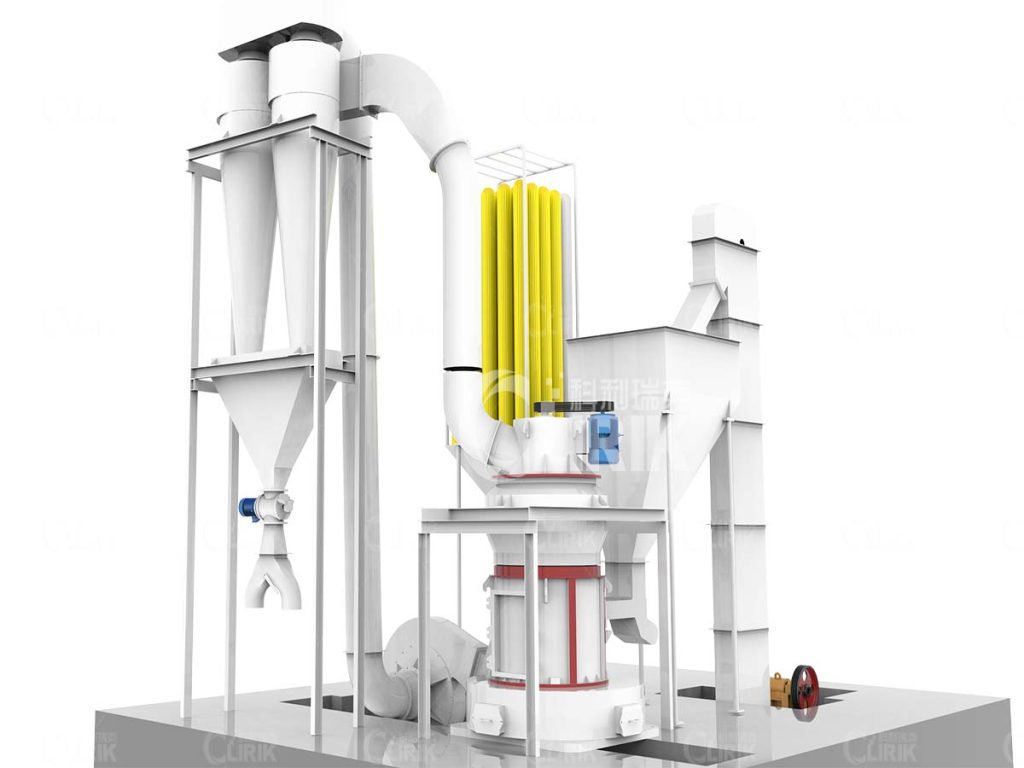

Clirik’s European Coarse Powder Mill is used in industries like metallurgy and construction, crushing rocks up to 320 MPa into coarse powder, with most particles under 3mm.

Clirik’s High Pressure Suspension Grinding Mill manages minerals up to hardness 9.3 and low moisture, offering fineness control from 50 to 325 meshes.

Shanghai CLIRIK Machinery Co.,Ltd. has dedicated itself to the ultrafine powder grinding machine industry for two decades.

Welcome to visit our factory in No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

You can leave a message online or contact CLIRIK directly: